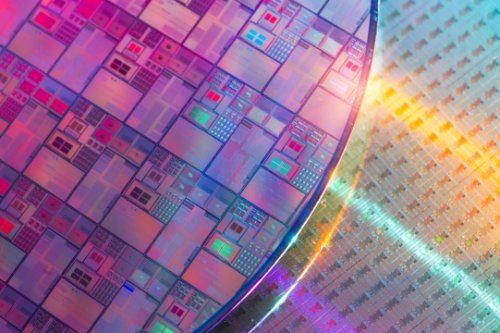

Etch

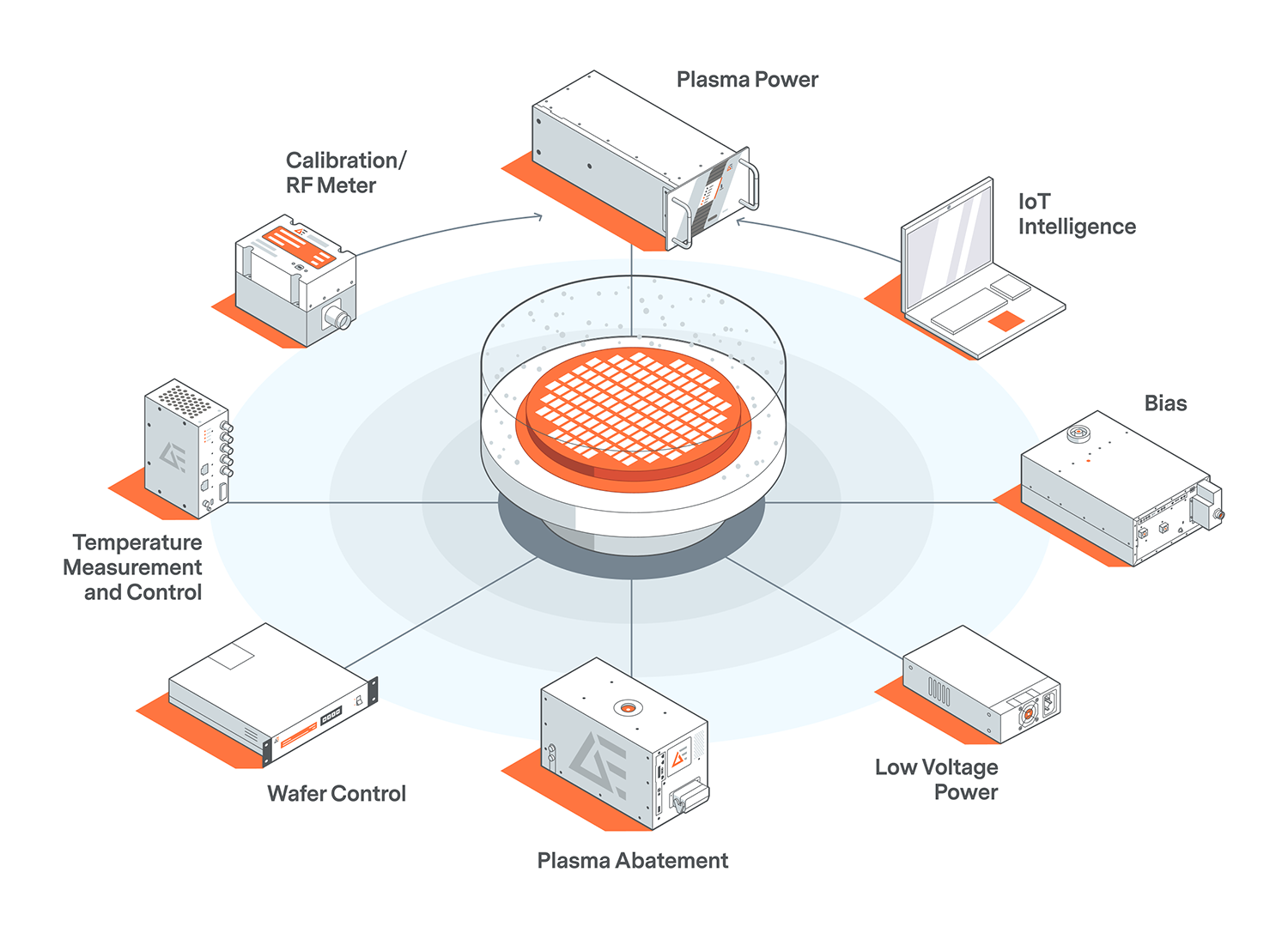

With sophisticated, high-precision plasma power delivery systems, Advanced Energy is at the forefront of technology for etching applications. Our solutions harness cutting-edge innovation to provide exacting power delivery and control throughout the etching process.

Comprehensive Portfolio of Solutions for Enhanced Process Control

AE's plasma power supplies are customized to suit the unique needs of each etching application. Our portfolio includes RF, DC, and pulsed-DC products, impedance matching networks, remote plasma sources, and a sophisticated data collection, visualization, and analysis platform. Built with cutting-edge technology, these solutions ensure exact, repeatable power delivery for superior process precision and yield.

Also see:

Featured Products

Featured Resources

PowerInsight by Advanced Energy Brochure

Three Key Cabling Decisions to Optimize RF System Performance

Navigator II Digital Matching Networks Brochure

Navigator II matching network provides rapid, accurate, and reliable matching across a wide range of power requirements. Download Navigator II Brochure for details regarding product specifications, electrical specifications, mechanical specifications and more

Electrostatic Semiconductor Wafer Clamping/Chucking System (ESC) Application Note

The electrostatic chuck (ESC) is used in a variety of semiconductor processes to hold the wafer during processing.

Technical Videos

.jpg?resizemode=force&maxsidesize=408)

.jpg?resizemode=force&maxsidesize=128)