Innova Series

Improve Process Efficiency and Reduce Waste using Gas Monitoring Solutions

Features

- Selectively measure a wide range of gases / vapors

- Reduce/eliminate calibration requirements

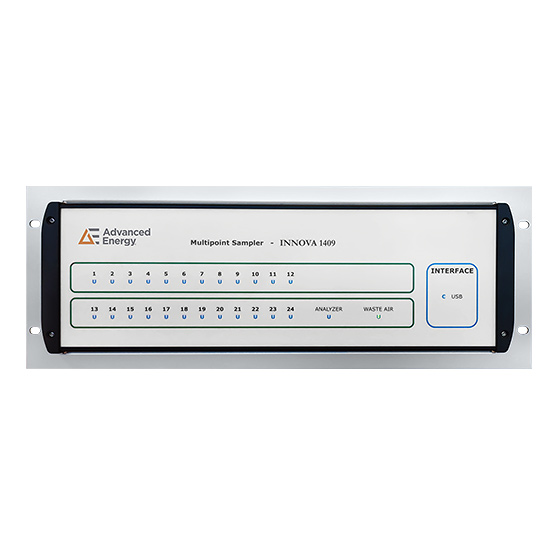

- Collect air samples from multiple locations

- Remotely control using the gas monitor or a PC

- Minimize expensive tracer gas consumption

- Achieve exceptional accuracy

- Promptly operate (rapid warm-up time)

Benefits

- Pneumatic system constructed of AISI-316 Stainless Steel and PTFE tubing to minimize gas adsorption

- Enabling all tracer gas methods

- Linear response over a wide dynamic range

- Independent from pressure or density readings

- Available in single or multiple gas configuration

- Multi-gas monitoring

Specifications

| Operational temperature range (°C): | 5 to 40 |

|---|---|

| Protection Class: | IP 20, IP 40 |

| Weight (kg): | 11 to 14 |

| CE-label: | CE-mark indicates compliance with: EMC Directive and Low Voltage Directive |

| Power Consumption (W): | 35 |

| Software: | 7650 Basic Ventilation Software, 7651 Advanced Ventilation Software, BZ7007, LumaSoft 7880, Windows® 7, 8, 8.1, and Windows® 10 |

Technical Documentation

Accessories

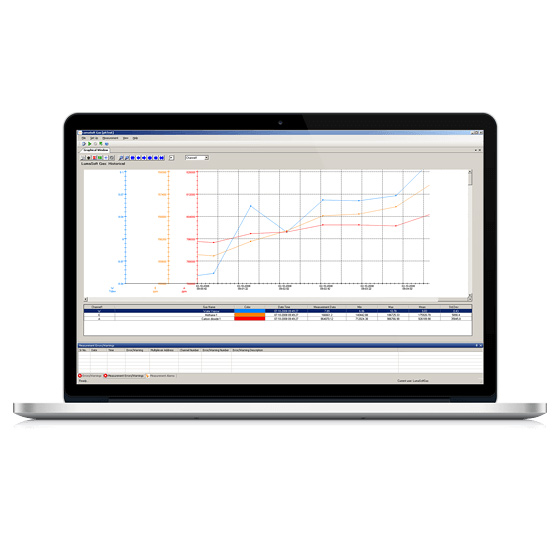

Innova LumaSoft Single Point 7820

Application Software for Single Channel Monitoring

Innova LumaSoft Multi Point 7880

Application Software to perform Gas Monitoring tasks in up to 24 locations

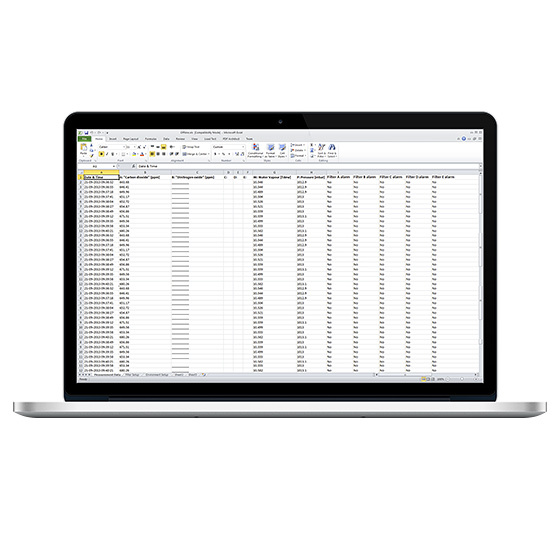

Innova BZ7003 Offline Software

Free version to set up the Gas Monitor without connecting it to a PC and to download gas monitor's data

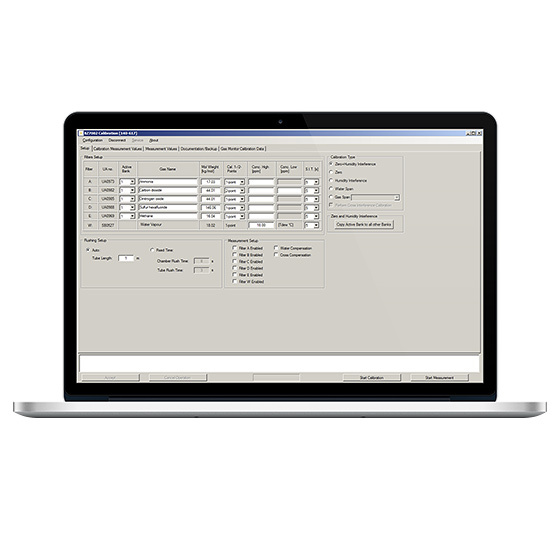

Innova BZ7002 Calibration Software

Free version to calibrate the gas monitor connecting it to a PC and back-up of the calibration data

Innova 7651 Advanced

Application Software for Monitor, Sampler, and Doser Remote Control

Innova 7650 Basic

Application Software for Ventilation and Air-Exchange Measurements

Innova BZ7007 Remote & Offline Software

BZ7007 Software is used during set-up and to retrieve data from a stand alone system where the gas monitor is used as the system controller

Related Applications

Explore All ApplicationsServices

Calibration and Alignment

Advanced Energy has the tools and processes to ensure your equipment continues to meet its original specifications. Our products are calibrated at global AE service sites with proprietary technology designed to exceed industry standards.

| Product Family | Calibration | Calibration with Alignment |

Total Support Package (TSP) |

||||||

|---|---|---|---|---|---|---|---|---|---|

| Term of Agreement | Annual | One Year | Two Years | Three Years | Five Years | One Year | Two Years | Three Years | Five Years |

| TEGAM 5540 | | | | | | | | | |

| Lumasense | | | | | | | | ||

| Plasma Power | | | | | | | |||

Repair

Our worldwide service centers provide fast cycle times, use only AE-qualified parts, and follow the original product's specifications and test procedures for the highest quality repair or calibration.

| Product Family | Calibration | Calibration with Alignment |

Total Support Package (TSP) |

||||||

|---|---|---|---|---|---|---|---|---|---|

| Term of Agreement | Annual | One Year | Two Years | Three Years | Five Years | One Year | Two Years | Three Years | Five Years |

| TEGAM 5540 | | | | | | | | | |

| Lumasense | | | | | | | | ||

| Plasma Power | | | | | | | |||

Service Agreements

Reduce annual maintenance costs and simplify forecasting by building a custom service agreement into your annual operating plan. We have the capability, expertise, and capacity to provide repair services, upgrades, refurbishments, exchange, and other service offerings to support maintenance and use of AE Products. We offer multi-year contracts and provide faster turnaround time for covered products.

| Product Family | Calibration | Calibration with Alignment |

Total Support Package (TSP) |

||||||

|---|---|---|---|---|---|---|---|---|---|

| Term of Agreement | Annual | One Year | Two Years | Three Years | Five Years | One Year | Two Years | Three Years | Five Years |

| TEGAM 5540 | | | | | | | | | |

| Lumasense | | | | | | | | ||

| Plasma Power | | | | | | | |||

Total Service Package

We offer customized service bundles that include calibration, alignment, and extended warranty. Services will include scheduled calibration with adjustment and repairs as needed. Any software/firmware upgrades are also made available for customers.

| Product Family | Calibration | Calibration with Alignment |

Total Support Package (TSP) |

||||||

|---|---|---|---|---|---|---|---|---|---|

| Term of Agreement | Annual | One Year | Two Years | Three Years | Five Years | One Year | Two Years | Three Years | Five Years |

| TEGAM 5540 | | | | | | | | | |

| Lumasense | | | | | | | | ||

| Plasma Power | | | | | | | |||