FurnaceSpection Series

Infrared Camera System for Continuous Reformer Tube Monitoring and Temperature Measurement Inside Furnaces

Mikron FurnaceSpection infrared imaging system offers real-time monitoring inside high temperature furnaces in refining, metals, and glass production. Advanced technology imaging offering clear visuals in harsh environments. Online analytics provide operators with instant critical data plus archiving for post process review. Radiometrically calibrated to measure temperatures of refractory and target objects in gas fired furnaces.

Features

- Advanced software with simultaneous acquisition from multiple cameras and advanced analytics

- Complete system integration with installation support

- Stainless steel lens with air cooling or optional water cooling (SD)

Benefits

- Monitor and control process temperature uniformity through real-time streaming images

- Identify process abnormalities before they develop into problems and unplanned outages

- Reduce cycle times and improve quality and process repeatability

- Measure temperature of product, refractory, and heat transfer surfaces

- Record and analyze data to optimize processes

Specifications

| Operational temperature range (°C): | 0 to 60 |

|---|---|

| Wavelength Range (nm): | 850 |

| Optical Interface: | Manual Focus |

| Number of Channels: | 1 |

| Accuracy: | ±2 deg C or 2% of reading |

| Measurement Rate (Hz): | 60 Hz |

| Field of View: | 55° to 72° |

| Filter (µm): | 0.85 |

Accessories

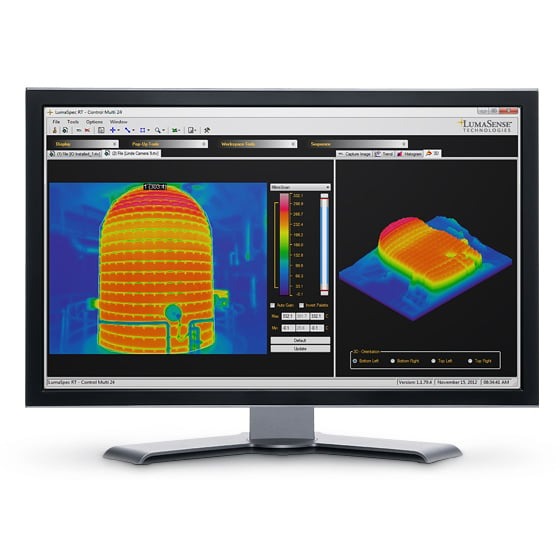

Mikron LumaSpec RT Software

Windows-Based, Real-Time Data Acquisition Software

Mikron LumaSpec Offline Analyzer 5.0

Advanced Thermal Image Processing, Analysis, and Report-Writing Software

Technical Documentation

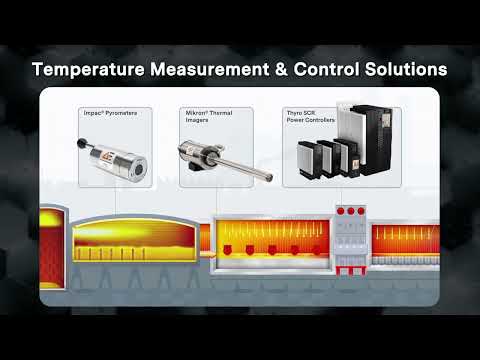

Technical Videos

From Sand to Shine: Optimizing Glass Production and Coating

Related Applications

Explore All ApplicationsServices

Calibration and Alignment

Advanced Energy has the tools and processes to ensure your equipment continues to meet its original specifications. Our products are calibrated at global AE service sites with proprietary technology designed to exceed industry standards.

Repair

Our worldwide service centers provide fast cycle times, use only AE-qualified parts, and follow the original product's specifications and test procedures for the highest quality repair or calibration.