Glass

Advanced Energy offers non-contact temperature sensors, SCR power controllers, and plasma power generators for greater process control, monitoring, and efficiency in glass production processes.

Advanced Temperature Monitoring & Power Control for Glass Manufacturing

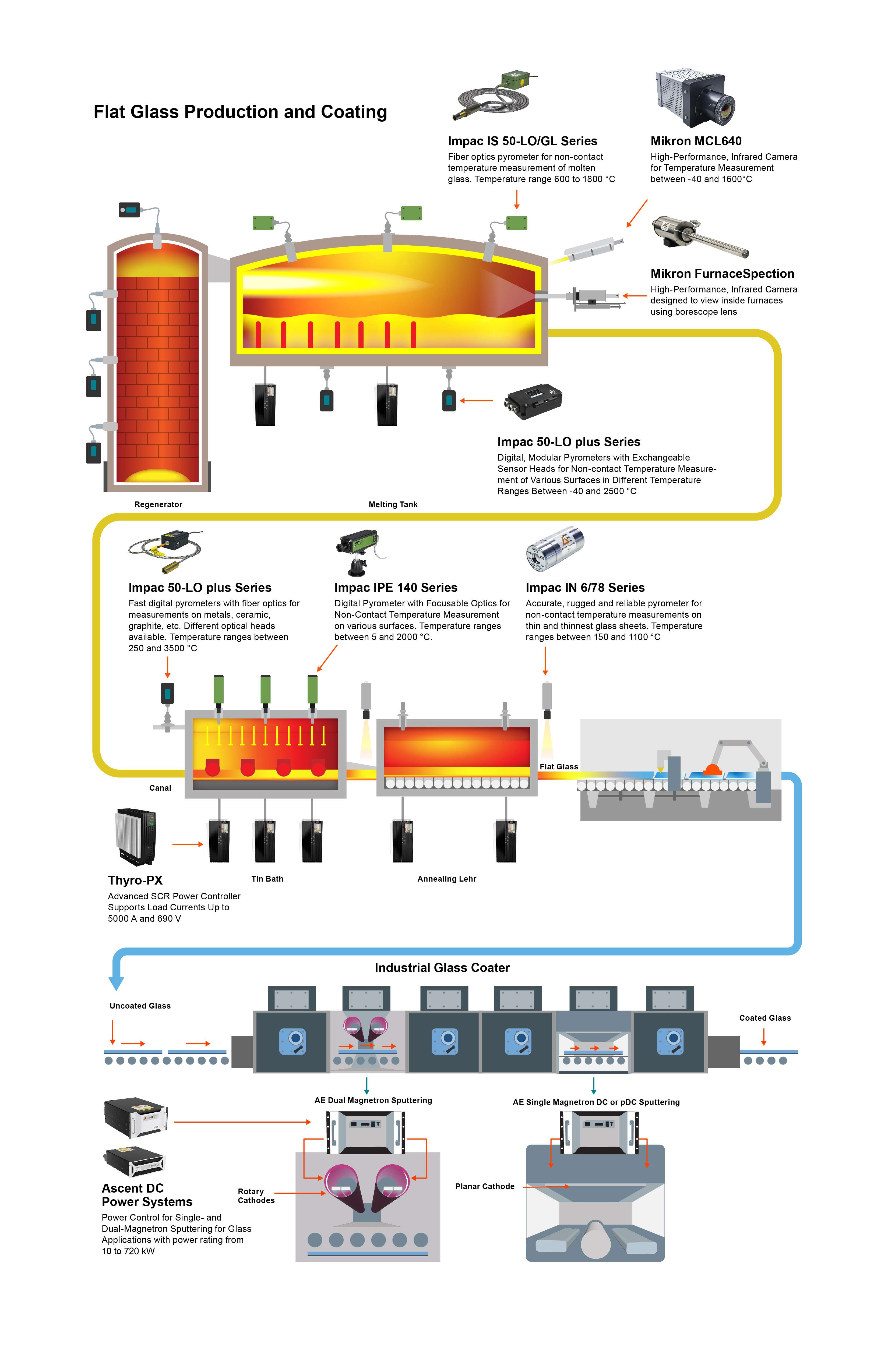

Advanced Energy offers leading technology for every phase of glass production:

Glass Melting, Flat Glass, Container Glass, and Specialty Glass

Accurate and precise temperature monitoring is critical for efficient and cost-effective melting, glass viscosity control, heat zone adjustment, annealing, and stress reduction. For decades, our instruments have been used in continuous and batch glass manufacturing processes around the world, where robustness and reliability are critical. Temperature measurement is also directly related to glass quality as well as prolonging the life of critical assets such as refractory walls.

New coating materials and layer stacks require advanced plasma power delivery solutions. Advanced Energy’s DC, pulsed DC, bipolar pulsed DC, and low-frequency AC solutions provide stable, reliable, precise power for innovative coating processes. Highly developed power delivery controls, including sophisticated arc management technology, increase uptime, deposition rates, and quality, while reducing cost of ownership.

.jpg?lang=en-US)

Featured Products

Featured Resources

Glass Production Solutions Brochure

Flat Glass Melt Tank Monitoring Application Note

Flat Glass Regenerator Application Note

Sheet Glass Production Application Note

IMPAC IS 50-LO/GL: Stability and Reliability in Regenerator Monitoring

Process Control for Glass Manufacturing Brochure

Plasma Power Delivery, Temperature Measurement, and Temperature Control

Molten Glass Case Study

Technical Videos