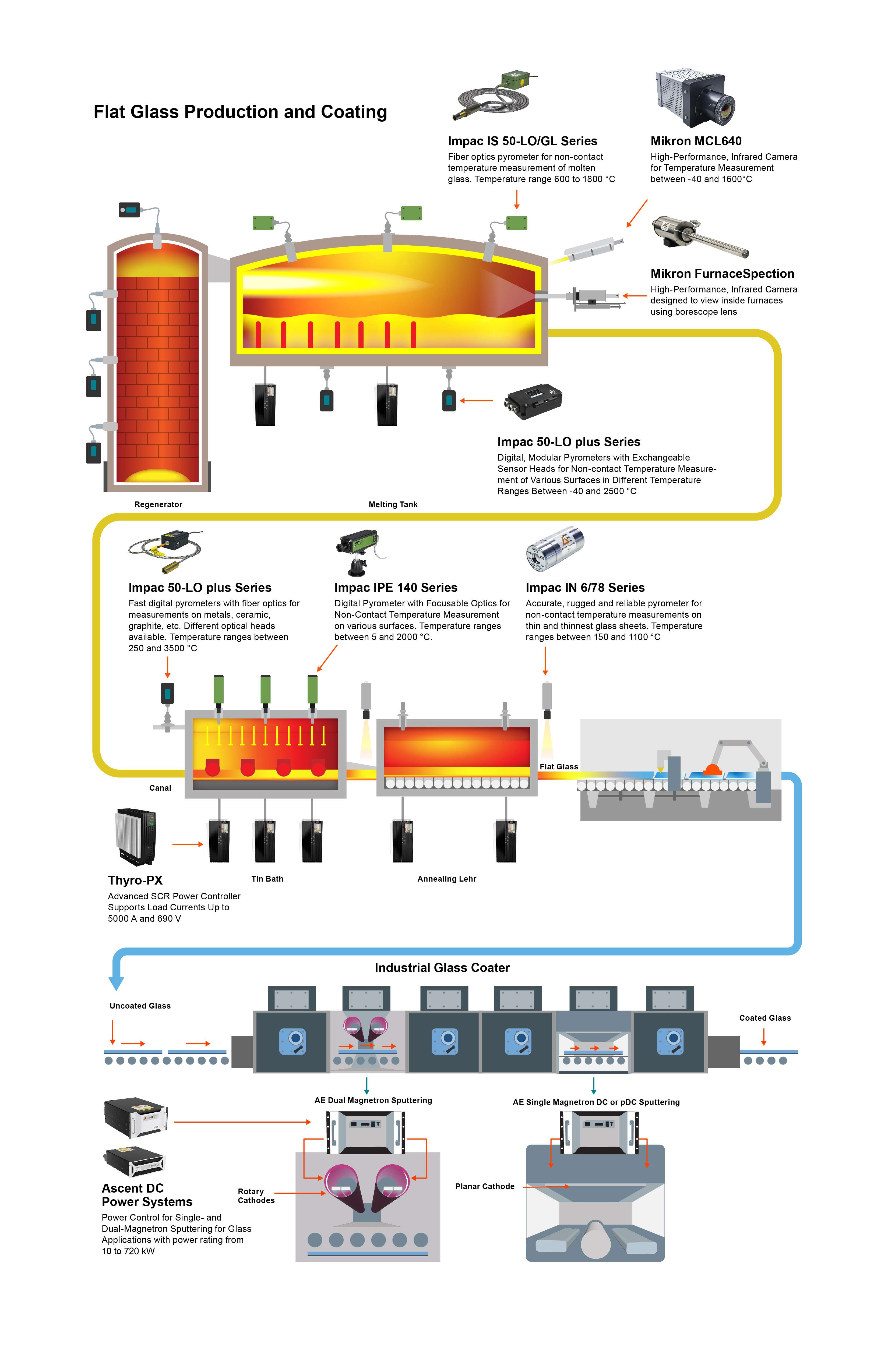

Advanced Energy's SCR power controllers handle low power output for sensitive glass melting by adjusting voltage and current via phase angle control. They ensure stable and accurate temperature regulation and provide precise control for continuous glass manufacturing applications where robustness and reliability are critical 24/7.

Thermal imagers are ideal for assessing overall temperature distribution and spotting thermal anomalies across larger surfaces in glass manufacturing. Pyrometers are best for measuring specific point temperatures and high heat areas. Advanced Energy offers both pyrometer and thermal imaging solutions to provide optimal technology for specific glass manufacturing applications, temperature requirements, and measurement scenarios.

Advanced Energy offers a comprehensive portfolio of plasma power delivery solutions that meet the diverse demands of glass coating applications. The optimal method depends on the specific coating process, substrate type, and desired film characteristics.

• DC and Pulsed DC: Ideal for single-magnetron sputtering and basic coating stacks. These methods provide stable power delivery and are enhanced by AE’s patented Dynamic Response Power (DRP) technology, which ensures rapid adaptation to process changes and maintains consistent film quality.

• Bipolar Pulsed DC: Best suited for dual-magnetron sputtering systems, this method offers advanced pulse shaping and precise control over deposition parameters. AE’s bipolar systems are designed to minimize arc events and maximize uptime, making them highly effective for complex layer stacks.

• Low-Frequency AC: Used in specialized applications where alternating current improves coating uniformity or addresses specific material challenges. AE’s solutions include customizable waveform control and proactive arc management to ensure high-quality results with minimal downtime.

• RF Power: RF plasma generators are increasingly used in large-area glass coating applications, especially where high-frequency control is needed for uniform deposition and fine-tuned ion energy. These systems are particularly effective for architectural and automotive glass coatings requiring high repeatability and process stability.

Across all methods, AE’s sophisticated arc management technology plays a critical role in reducing disruptions, increasing deposition rates, and improving overall coating quality to ultimately lower the total cost of ownership.

Temperature sensors require regular calibration, inspection for wear and contamination, and replacement of faulty components to maintain accuracy and reliability. AE’s non-contact temperature monitoring solutions are designed for reliable operation in harsh glass manufacturing environments, offering practical maintenance requirements and comprehensive support services.

At the heart of AE’s pulsed and DC power systems is the Arc Management System™ (AMS), Arc Sync®, and Set Point Compensation™ technology, which provide automatic arc handling, primary and secondary arc response, controlled power recovery, and low stored energy. These features are especially critical in large-area coating environments, where macro-particles from arcing can degrade film reliability, enabling automated power output adjustments to preserve sputter rates and coating uniformity.

Advanced temperature monitoring and power controls provide proven benefits for glass melting, forming, annealing, and coating applications. They enhance product quality, energy efficiency, and process precision. These solutions have decades of proven performance across all glass manufacturing sectors including architectural, automotive, solar PV, and flat panel display glass sectors.

• Architectural glass: High-throughput coating lines benefit from AE’s stable power delivery and arc suppression, ensuring uniform deposition and minimal downtime. Additionally, AE’s non-contact temperature sensors and thermal imagers enable closed-loop control of heating zones, improving coating uniformity and reducing stress-induced defects.

• Automotive glass: AE’s precision control supports complex multi-layer stacks and anti-reflective coatings, improving durability and optical clarity. Furthermore, AE’s temperature monitoring solutions help maintain consistent glass viscosity and annealing profiles, which are critical for safety and performance standards

• Solar PV and Flat Panel Display glass: AE’s bipolar pulsed DC and MF solutions enable high-quality thin-film deposition with repeatable film characteristics and reduced energy loss while AE’s temperature monitoring systems provide real-time feedback for heat zone adjustments, ensuring optimal substrate conditions and prolonging the life of critical assets like refractory walls.

.jpg?lang=en-US)