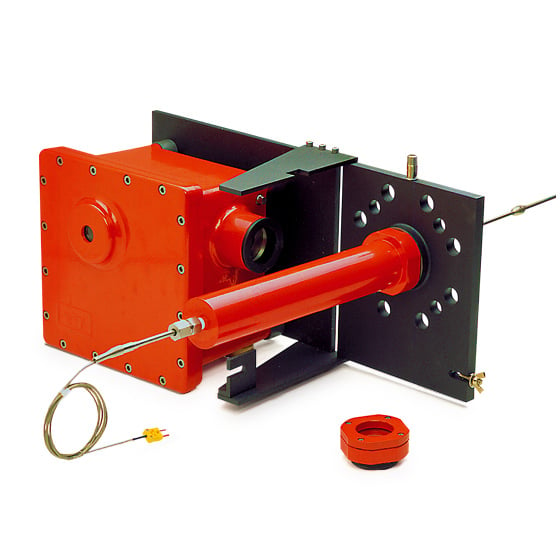

E²T Pulsar Sulfur Recovery Unit Pyrometer

Infrared Thermometry for Sulfur Reactors and High Temperature Furnaces

The E2T PulsarTM 4 Advanced measures two wavelengths for continuous and instantaneous measurement of refractory temperature (RT), gas temperature (GT) and integrated temperature (FF), reporting both readings simultaneously in one instrument. The E2T PulsarTM 4 is a single channel option for direct replacement of older Pulsar II models. The innovative Advanced Energy Smart FMA Flame Measurement Algorithm allows for accurate real-time flame transparency compensation and correction. Applying the flame transparency calculation with FMA removes the flame transparency errors due to the gas (flame) temperature, providing the highest accuracy in process temperatures.

Features

- Explosion-proof certification

- IECEx, ATEX II 2G EXd IIB+H2 T4,

- FM (US and CSA) Class I, Div I, Group B, C & D, T4

- regional certification like UKEx, KOSA, CCOE, INMETRO or TP/TC

- Integrated power supply, capable of operating with 24 VDC /120/230 VAC

- HART Rev 7 protocol (Advanced version only) and RS485 interface

- SmartFMA for highest GT and RT measurment

Benefits

- Prevent damage to the furnace refractory with high temperature alarms

- Install a single system with two independent infrared filtered detectors for gas (GT) and refractory (RT) measurements

- Quickly react to control the furnace process temperatures with instant readings

- Gain higher operational safety with accurate refractory measurement and high temperature alarms

- Use Smart FMA to remove flame transparency errors that typical pyrometers experience (Advanced version only)

Specifications

| Operational temperature range (°C): | 350 to 2000 |

|---|---|

| Measurement Uncertainty (°C): | 3°C + 1 digit |

| Ambient Temperature (°C): | -40 to 60 |

| Focus Range (mm/mtr): | 500 to Infinity |

| Ex-Rating: | IECEx db +H2 IIB T4 |

| Enclosure Material: | 316L stainless steel |

Technical Documentation

Technical Videos

Infrared Thermometry for Sulfur Reactors - Advanced Energy's E2T Pulsar 4

Related Applications

Explore All Applications