Calibration & Alignment

Advanced Energy recommends annual calibration and alignment to maintain measurement accuracy for most of our precision power and critical sensing products. Regular calibration ensures your equipment is operating within design specifications and is often required for quality system audits.

Ship your equipment to an AE service center near you by requesting an RMA or scheduling on-site support from our trained field engineers.

Ship your equipment to an AE service center near you by requesting an RMA or scheduling on-site support from our trained field engineers.

Temperature Sensing Products

Calibration and alignment of temperature sensing products like blackbodies, pyrometers, thermal imagers, and thermocouple thermometers are essential processes to ensure their accuracy and optimal performance traceable to national standards such as NIST and PTB.

Calibration of these instruments involves comparing their readings against a known standard to ensure accuracy, often with the use of a blackbody as a reference source.

Alignment, on the other hand, focuses on optimizing the performance of these instruments, sometimes within a specific system or application.

Blackbodies

All AE blackbodies are verified against a reference standard to ensure they are properly set up and stable. Calibration & Alignment for our Blackbody calibration sources at your site is available on all models except M315 and M345.

Pyrometers

Our expert technicians can adjust the pyrometer detector response to ensure the unit is optimized and operating within specifications and that the optical path is verified with the device focused correctly.

Thermal Imagers

Our expert technicians can adjust the thermal imager detector array response, such as by fixing points on the internal Lumens table for each pixel, adjusting the shape, and providing non-uniformity corrections (NUC), to ensure the unit is properly compensating for ambient conditions and operating within specifications.

Thermocouple Thermometers

Our service centers can calibrate AE's thermocouple thermometers to ensure precise, traceable measurements and maximize performance. Meet accredited standards to ensure calibration traceability to the National Metrology Institute, with detailed reports documenting each calibration procedure, results, and uncertainties.

Calibration of these instruments involves comparing their readings against a known standard to ensure accuracy, often with the use of a blackbody as a reference source.

Alignment, on the other hand, focuses on optimizing the performance of these instruments, sometimes within a specific system or application.

Blackbodies

All AE blackbodies are verified against a reference standard to ensure they are properly set up and stable. Calibration & Alignment for our Blackbody calibration sources at your site is available on all models except M315 and M345.

Pyrometers

Our expert technicians can adjust the pyrometer detector response to ensure the unit is optimized and operating within specifications and that the optical path is verified with the device focused correctly.

Thermal Imagers

Our expert technicians can adjust the thermal imager detector array response, such as by fixing points on the internal Lumens table for each pixel, adjusting the shape, and providing non-uniformity corrections (NUC), to ensure the unit is properly compensating for ambient conditions and operating within specifications.

Thermocouple Thermometers

Our service centers can calibrate AE's thermocouple thermometers to ensure precise, traceable measurements and maximize performance. Meet accredited standards to ensure calibration traceability to the National Metrology Institute, with detailed reports documenting each calibration procedure, results, and uncertainties.

Resources

Temperature Measurement Calibration Solutions

Information on Calibration programs available for Pyrometers, Thermal Imagers, and Blackbodies

View Resource

Tenneco Pyrometer Field Service Case Study

Discover how AE's Impac Pyrometers are used by Tenneco for process monitoring in their facility.

View Resource

Need a reminder?

Never forget a calibration! Stay accurate and meet your qualiity system audit requirements. Click below to set up an automatic reminder based on your calibration needs to contact AE at the right time.

Setup a Calibration Reminder

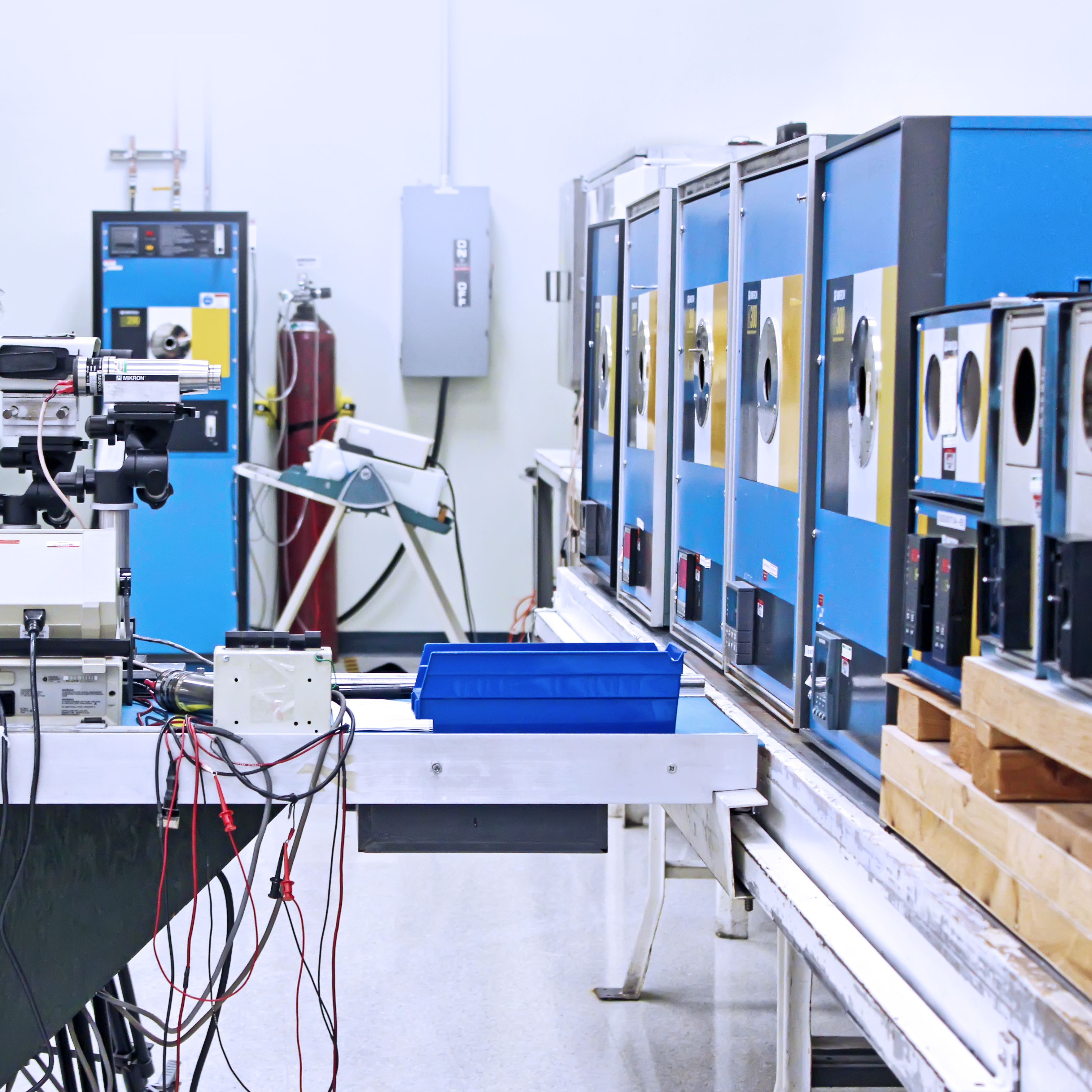

Plasma Power Products

Modern RF equipment contains advanced measurement devices and algorithms requiring regular calibration to ensure repeatable performance over time. Complex processes rely on the generator and match measurement systems to ensure repeatable power delivery. Units operating out of calibration are a risk to the quality of the processed wafer.

Advanced Energy's expertise in high power RF generation and measurement is key to consistency and repeatability in process control.

Using AE certified standards, our products are calibrated at global AE service sites with proprietary technology designed to exceed industry standards. For our most advanced products, we guarantee accuracy within 1% compared to the industry standard of 2%. Many of our sites are ISO 9001:2015 certified to satisfy the calibration and preventive maintenance requirements. AE can provide an exchange program to ensure no downtime due to calibration cycles.

Benefits

Advanced Energy's expertise in high power RF generation and measurement is key to consistency and repeatability in process control.

Using AE certified standards, our products are calibrated at global AE service sites with proprietary technology designed to exceed industry standards. For our most advanced products, we guarantee accuracy within 1% compared to the industry standard of 2%. Many of our sites are ISO 9001:2015 certified to satisfy the calibration and preventive maintenance requirements. AE can provide an exchange program to ensure no downtime due to calibration cycles.

Benefits

- Improved operating costs with increased yield and reduced downtime

- Confidence in measurements with more repeatability

- AE standards exceed industry performance

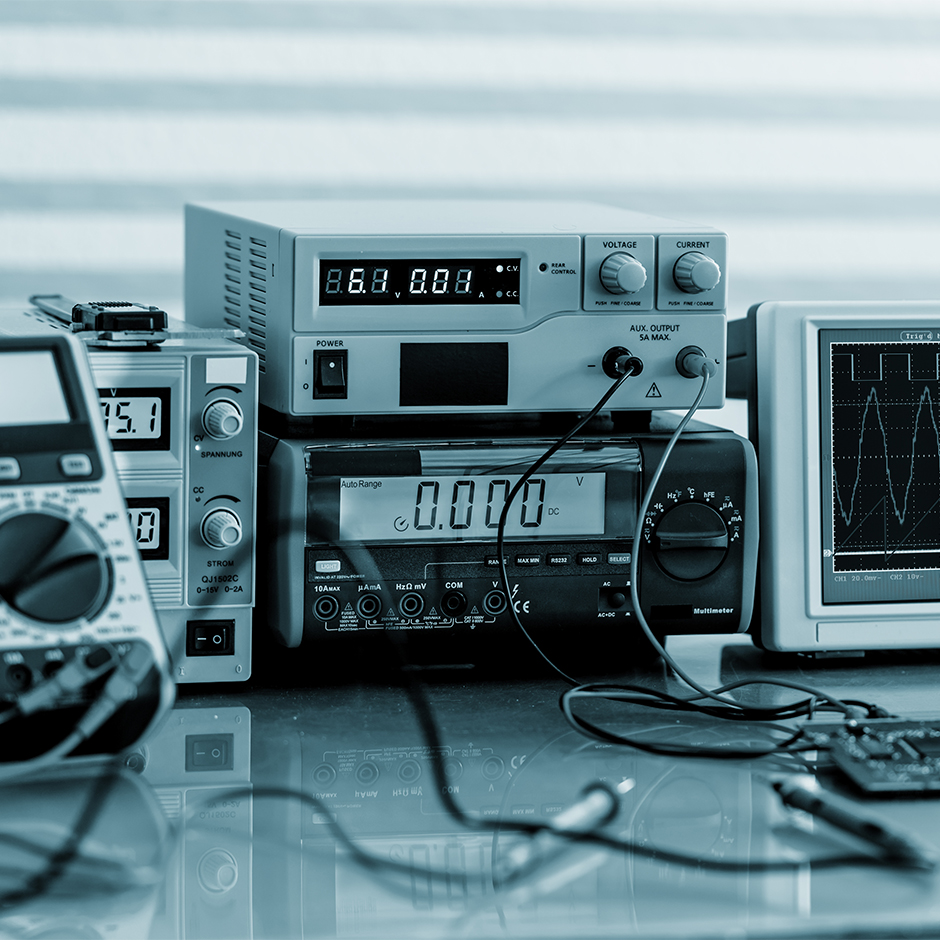

Electrostatic Voltmeters & ESD Instrumentation

Electrostatic Voltmeters

Calibration of electrostatic voltmeters involves formal procedures to ensure the accuracy of measurements. These methods are based on measurements whose accuracy can be traceable to the National Institute of Standards and Technology (NIST) and conform to the requirements of ISO/IEC 17025 and ANSI/NCSL Z540-1.

Regular calibration is necessary to accurately measure surface potential (voltage) on materials and to maintain electrostatic voltmeter compliance with quality standards.

Electrostatic Discharge (ESD) Instrumentation

Calibration of ESD instrumentation involves a variety of checks and adjustments to ensure the device operates correctly. These methods are based on measurements whose accuracy can be traceable to the National Institute of Standards and Technology (NIST) and conform to the requirements of ISO/IEC 17025 and ANSI/NCSL Z540-1.

Regular calibration of charge plate monitors, sensors, resistivity meters, field meters, and voltmeters is necessary to reliably monitor, measure, and locate electric charge, surface voltage, and resistivity. Additionally, regular ESD instrumentation calibration is necessary to maintain compliance with quality standards.

Calibration of electrostatic voltmeters involves formal procedures to ensure the accuracy of measurements. These methods are based on measurements whose accuracy can be traceable to the National Institute of Standards and Technology (NIST) and conform to the requirements of ISO/IEC 17025 and ANSI/NCSL Z540-1.

Regular calibration is necessary to accurately measure surface potential (voltage) on materials and to maintain electrostatic voltmeter compliance with quality standards.

Electrostatic Discharge (ESD) Instrumentation

Calibration of ESD instrumentation involves a variety of checks and adjustments to ensure the device operates correctly. These methods are based on measurements whose accuracy can be traceable to the National Institute of Standards and Technology (NIST) and conform to the requirements of ISO/IEC 17025 and ANSI/NCSL Z540-1.

Regular calibration of charge plate monitors, sensors, resistivity meters, field meters, and voltmeters is necessary to reliably monitor, measure, and locate electric charge, surface voltage, and resistivity. Additionally, regular ESD instrumentation calibration is necessary to maintain compliance with quality standards.