Enhanced Temperature Measurement Accuracy for Optimized Industrial Production

Posted August 13, 2025 by Tim Dubbs

Blog Summary:

1. Precision in Temperature Measurement is Crucial Across Industries

Accurate temperature control directly impacts product quality, process efficiency, and yield in industries like petrochemical refining and steel annealing. Non-contact infrared methods, such as thermal imagers, are increasingly preferred for their speed, safety, and broad coverage.

2. Thermal Reflections can Compromise Infrared Readings

Infrared-based systems often capture not only emitted radiation but also reflected energy from surrounding surfaces, leading to inaccurate temperature measurements—especially during temperature ramp-up or cooling phases.

3. Advanced Energy’s (AE’s) Patented Algorithms Solve Reflection Challenges

AE’s FurnaceSpection™ system uses multiple thermal cameras and a patented algorithm to correct for emissivity and reflections in real time. This enables highly accurate surface temperature readings, improving process control, product consistency, and manufacturing yield.

1. Precision in Temperature Measurement is Crucial Across Industries

Accurate temperature control directly impacts product quality, process efficiency, and yield in industries like petrochemical refining and steel annealing. Non-contact infrared methods, such as thermal imagers, are increasingly preferred for their speed, safety, and broad coverage.

2. Thermal Reflections can Compromise Infrared Readings

Infrared-based systems often capture not only emitted radiation but also reflected energy from surrounding surfaces, leading to inaccurate temperature measurements—especially during temperature ramp-up or cooling phases.

3. Advanced Energy’s (AE’s) Patented Algorithms Solve Reflection Challenges

AE’s FurnaceSpection™ system uses multiple thermal cameras and a patented algorithm to correct for emissivity and reflections in real time. This enables highly accurate surface temperature readings, improving process control, product consistency, and manufacturing yield.

Precise temperature control is critical across many industries. While high-accuracy probes are available, optical-based systems like pyrometers and thermal imagers can have their readings compromised by thermal reflections, leading to inaccurate measurements. This blog discusses how Advanced Energy’s (AE’s) patented algorithms overcome these challenges to enhance process control, product quality and manufacturing yield.

Precise measurement and control of temperature is absolutely critical in a wide variety of industrial applications ranging from petrochemical reformers - where catalysts modify the molecular structure in an endothermic process - to the steel annealing processes used to improve the ductility, durability, or electrical conductivity of a metal or alloy. Indeed, the accuracy of measurement and the precision of control have a direct impact on the quality of the finished product, process yield or system efficiency.

Precise temperature measurement

Various methods for monitoring temperatures exist including traditional contact methods based on technologies such as thermocouples and RTDs. However, these are increasingly being replaced with non-contact, automated approaches that are typically based on infrared measurements. Such techniques offer rapidresponse, are compatible with high-temperature environments and do not interfere with the target being measured. In addition, they can view a large area rather than the limited points where a thermocouple is mounted.

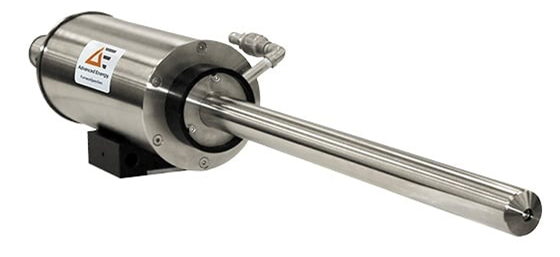

Figure 1: Advanced Energy’s FurnaceSpection infrared thermal

Figure 1: Advanced Energy’s FurnaceSpection infrared thermal camera for use in petrochemical and annealing furnaces

A good example of the latest infrared measurement techniques can be found in Advanced Energy’s FurnaceSpection™ system. This is based upon the Mikron® MCS640 imager coupled to a water- or air-cooled stainless steel borescope lens that allows continuous monitoring inside furnaces. The 850 nm wavelength is specifically selected to permit the thermal camera system to ‘see through’ the flames present in gas-fired furnaces.

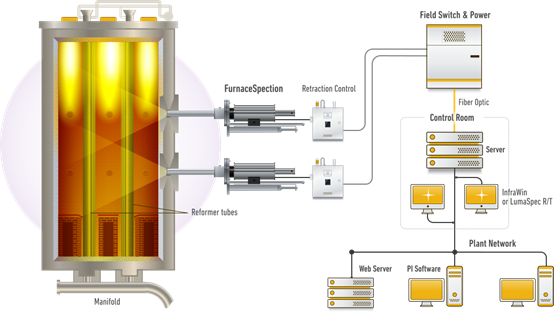

Figure 2: An annealing furnace set up based on

Figure 2: An annealing furnace set up based on AE’s FurnaceSpection infrared thermal cameras

A typical system will consist of multiple FurnaceSpection thermal imagers, with the number dictated by the size of the furnace and coverage required. These systems are installed through a small hole in the furnace wall, leaving the camera electronics outside. Integrated pneumatic mechanisms automatically retract and protect the borescope if there is a disruption to the power or cooling system. The cameras also use positive air pressure that prevents lens contamination, and an optional purge system to avoid any explosive gases from seeping into them when used in hazardous atmospheres.

The challenge of reflectivity

Thermal imaging cameras use the infrared spectrum to measure the thermal radiation emitted from an object in watts. Infrared power increases by the fourth power of the object temperature (measured in Kelvin), so a doubling of temperature results in 16 times the power. So, an object at 200 °C (473.15 K) emits 2.6 times the power of the same object at 100 °C (373 K).

However, a challenge arises because the infrared energy collected includes not only the radiation emitted by the target object, but also reflections from nearby, often hotter, surfaces. These reflected signals—from sources like walls, lamps, or burners—can interfere with the measurement, leading to significantly inaccurate temperature readings.

The extent to which reflections occur is related to the emissivity (ϵ) of a surface. Reflection (r), r = 1.0 – ϵ. The reflected energy can cause an infrared-based thermal imager to give an inaccurate reading. This is particularly likely while temperatures are ramping up or down when thermal differences are at their greatest, or in endothermic processes such as a petrochemical reformer.

Compensating for reflected infrared energy – a novel approach

In a ‘typical’ furnace setup multiple thermal cameras are positioned and angled to provide full coverage. Their position is defined by the field-of-view (FOV) of each lens and the required spatial resolution. The primary areas of interest are the solid angle and distance to the objects to be measured, and the locations of other objects in the furnace. In addition, the presence of residual flame signatures can also be considered. These conditions require that a three-dimensional model of the furnace be constructed to optimize the solution.

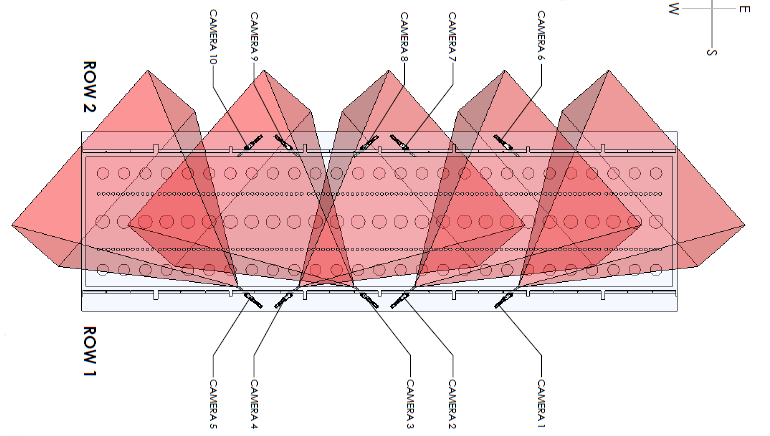

Figure 3: A multi-camera setup to deliver highly accurate

Figure 3: A multi-camera setup to deliver highly accurate temperature measurements and minimize the problems of reflections.

Modern infrared cameras are able to each take multiple readings through software-defined regions of interest (ROIs), allowing extensive temperature measurements – with just 10 pixels needed for an accurate reading.

Through this multi-camera approach, it is possible to better factor in emissivity and reflections. Advanced Energy is a leader in this area and has developed and patented an advanced algorithm that combines the multiple temperature measurement datapoints with atmospheric and reflection corrections to calculate true surface temperatures for objects within the furnace. These calculations are performed continuously at 1Hz, for continuous monitoring and optimization of the furnace.

AE’s thermal camera systems and these novel algorithms are already in use within the petrochemical industry, where it has been possible to achieve a corrected accuracy of +/-10 °C with typical furnace temperatures on the order of 1600 °C. This meets the requirements for annealing or petrochemical processes.

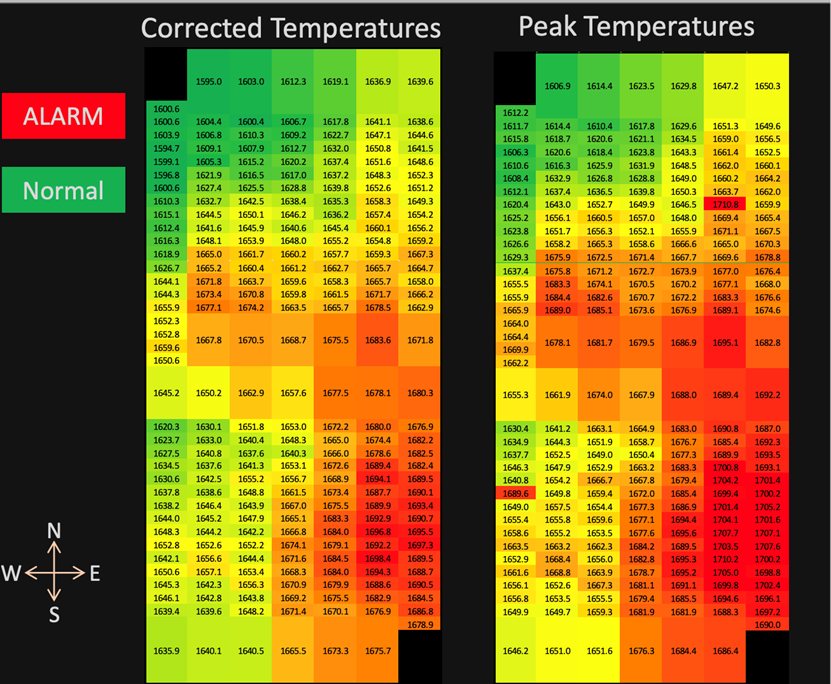

Figure 4: Corrected temperatures (left) and peak temperatures

Figure 4: Corrected temperatures (left) and peak temperatures (right) as calculated by AE’s LumaSpec algorithms

The Advanced Energy solution

Advanced Energy is unique in providing a complete end-to-end service that encompasses a site survey and camera location planning as well as installation, commissioning and system verification. As part of this service, we can model the furnace and configure the algorithm to its exact parameters and, therefore, minimize the issue of reflections – including during the ramp and cooling phases.

As regards the hardware, the MCS640 thermal imager offers 0.06 °C sensitivity and +/-0.5 % camera accuracy across a 600 °C to 1700 °C range, while the high-resolution 640 x 480-pixel sensor can be configured with multiple ROIs, allowing multiple areas to be measured simultaneously.

Figure 5: Through AE’s algorithms, the LumaSpec software is able to identify

Figure 5: Through AE’s algorithms, the LumaSpec software is able to identify the temperature of each tube where resolution permits (tubes 1 to 17 in the above)

and correct for reflections of the hotter walls/floors. Holes on the right side are

burner ports where the flame is not visible with our special TI camera wavelength.

The borescope multi-element lenses are available with a FOV of 54°H x 42°V and are made from 310 stainless steel, a high-chromium, nickel austenitic stainless steel known for its excellent high-temperature properties, including oxidation and corrosion resistance. As standard these cameras are air cooled, however water cooling is also available as an option for use with larger-diameter lenses.

Advanced Energy’s LumaSpec™ software sits at the heart of the system and receives inputs from the multiple thermal cameras. Within the software is the patented correction algorithm for reflection compensation.

Connection to the control room is via MODBUS over TCP/IP, allowing operators access to key information including corrected surface temperature, maximum surface temperature, camera temperature, retraction state and several useful status alarms.

LumaSpec can be combined with a web-enabled real-time trending software allowing detailed information about the furnace status to be monitored remotely.

Advanced Energy’s integrated solution combines real-time reflection correction with continuous temperature monitoring to ensure highly accurate process temperature measurements. This precision enables optimal furnace balancing, delivering the consistent, repeatable process control manufacturers need to boost product quality, maximize yield, and gain a competitive edge.

Learn more about Advanced Energy's thermal imagers and systems, which accurately measure temperature using ultra-reliable infrared technology: https://www.advancedenergy.com/en-us/products/sense-and-measurement/thermal-sensing/thermal-imagers-systems/.

Tim Dubbs

Advanced Energy

Tim Dubbs is Advanced Energy’s Director, Apps Engineering – Industrial Power, System Power.

More posts by Tim Dubbs