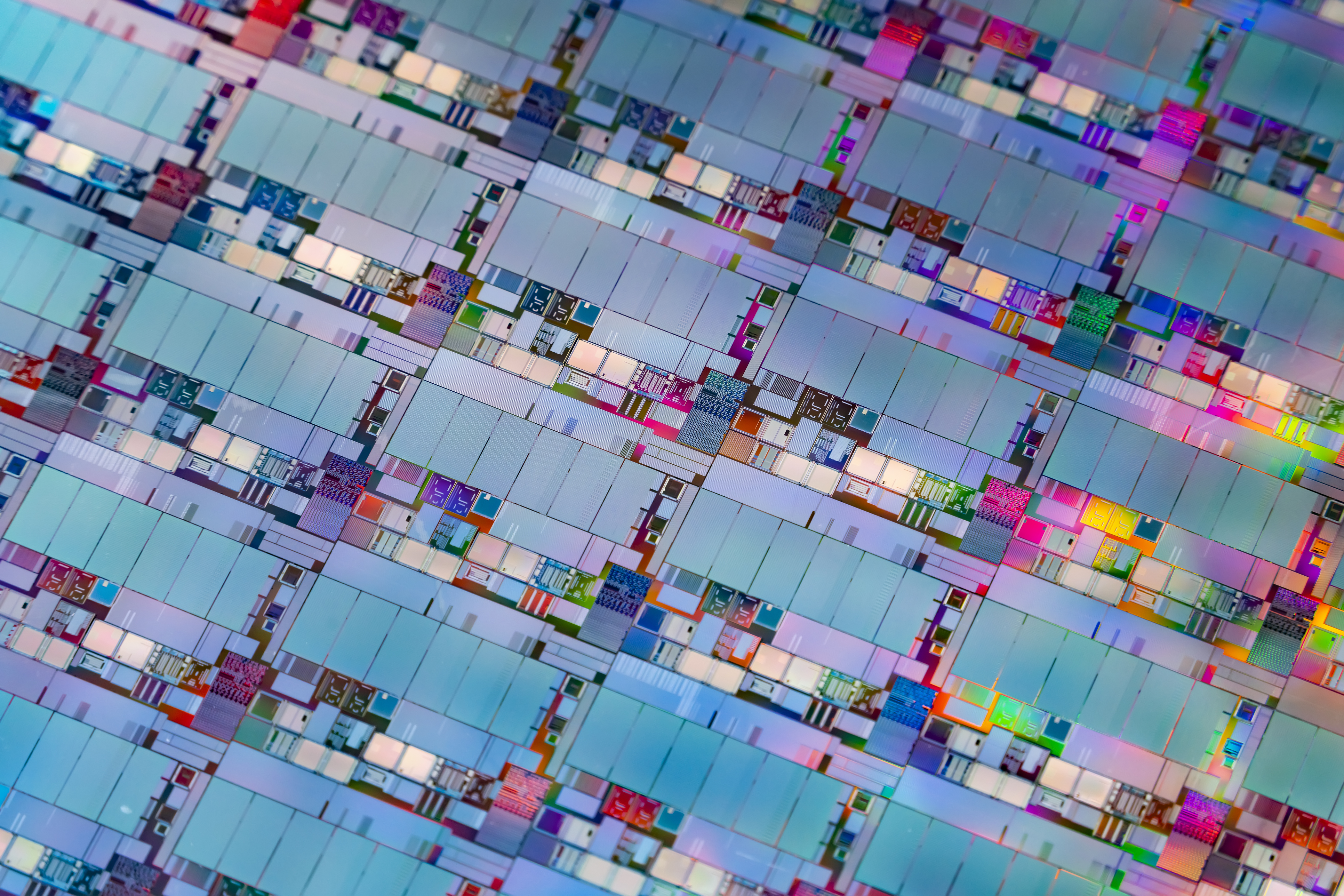

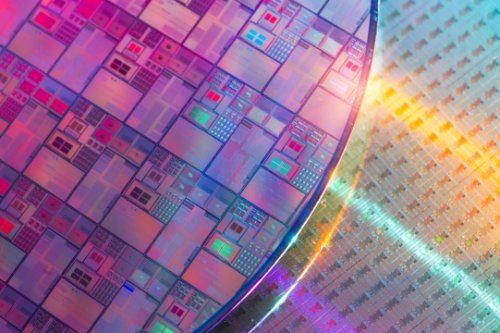

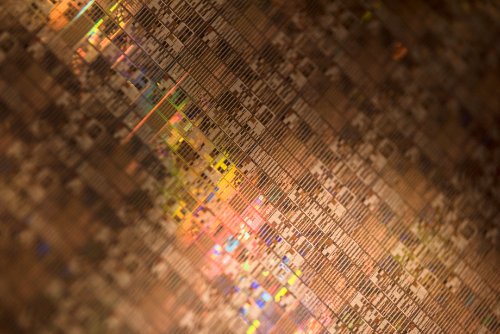

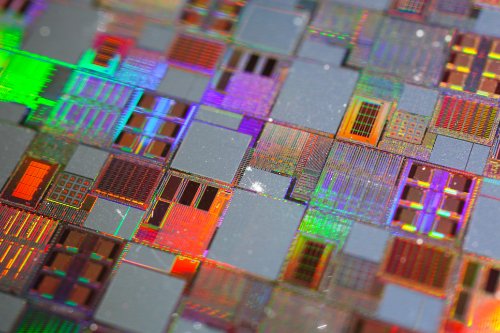

Semiconductor

Semiconductor Applications

Deposition

AE offers a comprehensive portfolio for semiconductor deposition, including plasma power delivery, temperature measurement, temperature control, and wafer control solutions.

Etch

Advanced Energy's high-precision plasma power delivery systems provide exacting control of etch applications for high repeatability and yield.

Electron Beam Inspection

Advanced Energy delivers stable, reliable power to electron beam inspection systems. This exacting control enables highly accurate defect identification, ensuring that memory and logic devices meet stringent specifications.

Implant

AE power products are engineered with a focus on optimizing efficiency and power density to ensure precise control of ion energy.

RF Generator Calibration

Utilizing Advanced Energy power meters for field calibration of RF generators maintains accuracy and confidence in your semiconductor processing equipment.

Strip

Precision control of power in plasma etching is critical to ensure flawless stripping of the wafer surface, leaving it free of any potential defects.

New

NavX™

Ultrafast, RF-synchronized Tuning to Multi-Level Pulse States

Featured Products

Featured Resources

Etching and Wafer Fab Equipment Application Note

RPS Chamber Anodization White Paper

Electrostatic Semiconductor Wafer Clamping/Chucking System (ESC) Application Note

3 Tips for Sourcing Chamber Cleaning RPS Systems

Critical Sensing and Control Product Portfolio

Semiconductor Case Study