BoilerSpection SD Series

Mobile and Turnkey Infrared Camera for Clear and Continuos Imaging inside Boilers and Furnaces

Features

- IR imaging with cooled borescope lens

- Special mid-wave infrared detector to see through flames

- Measure temperature across entire image

- Removable radiation shield with mobile/semi-permanent model

- Automatic retraction system with weld/bolt model

- Compatible with BoilerSpection continuous monitoring solution

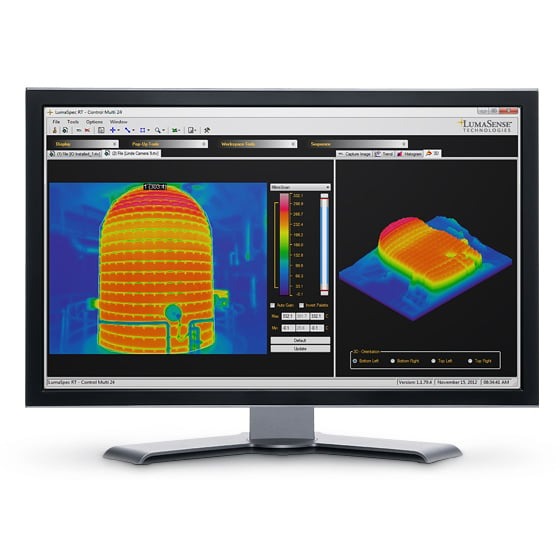

- Included LumaSpec Real-Time (RT) or Offline tool for data analysis

- Network software system integrated into plant DCS

- Full-service field installation and maintenance options

Benefits

- Increase efficiency by improving heat transfer

- Capture lost boiler capacity by reducing cleaning frequency

- Lower maintenance costs by optimizing cleaning

- Inspect build-up of ash/slag on boiler tubes

- Pinpoint problems, such as clinkers, before they cause outages

- Diagnose burner flame conditions

- Record and analyze data to optimize combustion processes

- Optimize fuel switching strategies with ash rate and uniformity tracking

- Speed up boiler light off and regulate fuel and airflow for lower consumption

- Reduce emissions and improve safety

Specifications

| Operational temperature range (°C): | 0 to 60 |

|---|---|

| Wavelength Range (nm): | 3900 |

| Optical Interface: | Manual Focus |

| Number of Channels: | 1 |

| Accuracy: | ±2 deg C or 2% of reading |

| Measurement Rate (Hz): | 9 Hz, 50 Hz |

| Field of View: | 50° to 72° |

| Filter (µm): | 3.9 to 5.2 |

Accessories

Mikron LumaSpec Offline Analyzer 5.0

Advanced Thermal Image Processing, Analysis, and Report-Writing Software

Mikron LumaSpec RT Software

Windows-Based, Real-Time Data Acquisition Software

Technical Documentation

Related Applications

Explore All ApplicationsServices

Calibration and Alignment

Advanced Energy has the tools and processes to ensure your equipment continues to meet its original specifications. Our products are calibrated at global AE service sites with proprietary technology designed to exceed industry standards.

Repair

Our worldwide service centers provide fast cycle times, use only AE-qualified parts, and follow the original product's specifications and test procedures for the highest quality repair or calibration.