Leveraging the Full Potential of Data for Efficient Semiconductor Fabrication

Posted June 23, 2025 by Jing Li

Turning total power system data into actionable insights to reduce operational costs and avoid downtime

Blog Summary

• Operational Challenges in Semiconductor Fabs: Semiconductor manufacturers face persistent issues like unplanned downtime, delayed troubleshooting, and costly no problem observed (NPO) returns. Plasma power products, though critical, are often underutilized in addressing these challenges.

• PowerInsight’s Transformative Capabilities: PowerInsight by Advanced Energy® enhances diagnostics by collecting and analyzing detailed operational data from RF/DC power supplies. It enables faster root-cause analysis, reduces mean time to recovery (MTTR), and supports preventative maintenance through features like FastDAQ event capture and web-based dashboards.

• Path to Predictive Maintenance: By leveraging historical and real-time data, PowerInsight lays the groundwork for predictive maintenance using machine learning models. This approach helps identify potential failures early, optimize performance, and significantly cut operational costs.

• Operational Challenges in Semiconductor Fabs: Semiconductor manufacturers face persistent issues like unplanned downtime, delayed troubleshooting, and costly no problem observed (NPO) returns. Plasma power products, though critical, are often underutilized in addressing these challenges.

• PowerInsight’s Transformative Capabilities: PowerInsight by Advanced Energy® enhances diagnostics by collecting and analyzing detailed operational data from RF/DC power supplies. It enables faster root-cause analysis, reduces mean time to recovery (MTTR), and supports preventative maintenance through features like FastDAQ event capture and web-based dashboards.

• Path to Predictive Maintenance: By leveraging historical and real-time data, PowerInsight lays the groundwork for predictive maintenance using machine learning models. This approach helps identify potential failures early, optimize performance, and significantly cut operational costs.

Challenges in Semiconductor Fabrication

In today’s competitive manufacturing, the pressure to reduce operational costs while maintaining efficiency and uptime is greater than ever. Challenges like unplanned downtime, costly spare unit inventory, delayed troubleshooting, and the ripple effects of no problem observed (NPO) returns on production, labor, and logistics continue to weigh heavily on fabs and their suppliers.

At the heart of semiconductor manufacturing, plasma power products play a critical role, yet they often hold untapped potential to transform operations. Every plasma power unit generates a wealth of operational data, and PowerInsight by Advanced Energy® enables customers to leverage the full potential of data and use it to drive measurable improvements.

Introducing PowerInsight by Advanced Energy

In today’s competitive manufacturing, the pressure to reduce operational costs while maintaining efficiency and uptime is greater than ever. Challenges like unplanned downtime, costly spare unit inventory, delayed troubleshooting, and the ripple effects of no problem observed (NPO) returns on production, labor, and logistics continue to weigh heavily on fabs and their suppliers.

At the heart of semiconductor manufacturing, plasma power products play a critical role, yet they often hold untapped potential to transform operations. Every plasma power unit generates a wealth of operational data, and PowerInsight by Advanced Energy® enables customers to leverage the full potential of data and use it to drive measurable improvements.

Introducing PowerInsight by Advanced Energy

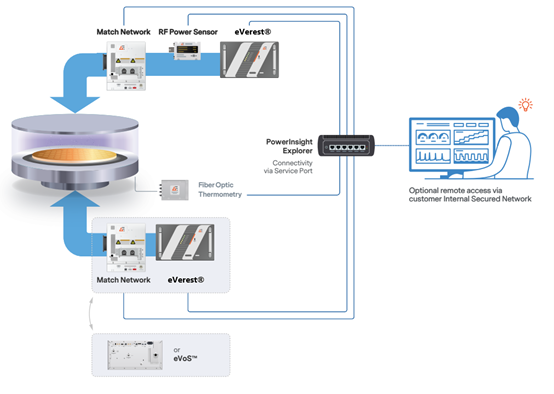

PowerInsight is designed to integrate seamlessly with Advanced Energy’s RF and DC power supplies and impedance matching networks, reading comprehensive data through the service port. While customer data collection systems are often in place today, they are focused on overall process monitoring. PowerInsight collects complementary data from plasma power supplies to provide critical information on unit health, in-depth troubleshooting and preventative maintenance. The complementary data includes the complete sets of time-stamped fault and warning logs, plasma generator statistics and configuration, firmware verification, internal sensor readings, and FastDAQ™ event captures.

Case Study

One example shows how PowerInsight can help reduce root-cause analysis time from days to hours across different tools, platforms, and customer sites.

A customer reported that their eVoS® unit showed an unknown fault code during regular operation.

To keep operations running, engineers have historically relied on the following workarounds:

- Power cycling or swapping out the generator: this is a temporary fix that may clear the system fault symptomatically but leave the root cause unresolved or risk unnecessary NPO returns.

- Calling in field engineers to determine the root cause: this requires scheduling chamber time to attempt to manually reproduce the issue before collecting and analyzing the fault data. Unfortunately, this method often misses historical context and key indicators and wastes valuable tool time.

In this instance, where PowerInsight had been deployed on the tool, AE’s subject matter experts remotely accessed historical plots to analyze the fault code and other key process data. They determined that the performance issue occurs during switching between low voltage and high voltage required a firmware update. AE was able to confirm the required firmware to install on the eVoS unit within hours of the initial notification. This eliminated the need to schedule chamber down time for a detail root-cause analysis by painstakingly piece together all the relevant information to provide a solution. Later, once the firmware update was ready, AE deployed a local field application engineer to install at the customer’s location.

This example is not unique. Similar troubleshooting challenges occur frequently across various tools, where customers often lack either complete datasets or the expertise to interpret the available logs. By making sufficient and intuitive data readily available, PowerInsight empowers experts with the know-how to troubleshoot efficiently. This seamless combination of data and expertise has reduced root-cause analysis time by 70-90% based on recent deployments, preventing unnecessary returns, and minimizing mean time to recovery (MTTR).

View Oscilloscope-level Event Data Directly Through Web Browser

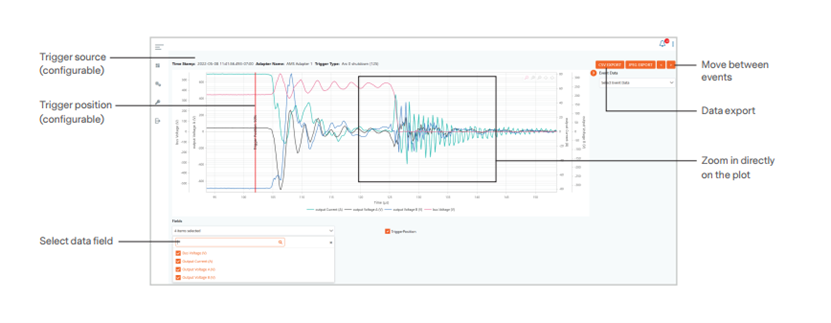

When deployed on products with FastDAQ (fast data acquisition) capability, such as the eVerest® RF generator, PowerInsight captures oscilloscope-level event data. This is especially beneficial in production environments where, due to safety restrictions, oscilloscopes cannot be installed. All captured data is instantly available in a centralized dashboard accessible via a web browser.

Review FastDAQ event on web-browser

Furthermore, PowerInsight features Smart FastDAQ that goes beyond a single FastDAQ capture. It continuously adapts its trigger and other configuration parameters to the power condition changes, hunting for all critical moments in the process.

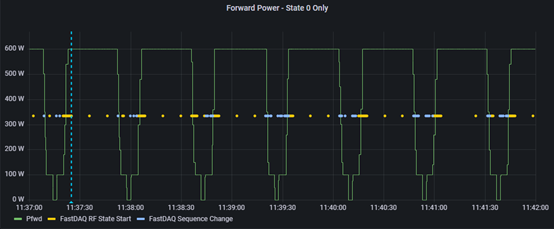

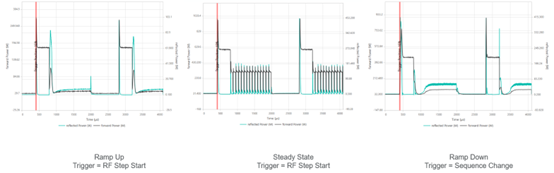

For example, to capture multi-level pulsing FastDAQ signals on an eVerest RF generator, PowerInsight Smart FastDAQ was configured to automatically set different trigger types as follows:

- At startup, set the trigger type to ‘[On] Sequence Change’,

- When the unit reaches “steady state”, reset trigger type to ‘RF State Start’,

- Reset trigger type to ‘[On] Sequence Change’ when the forward power begins to ramp down,

- Then ‘powered off’ reverts to xyz trigger, avoiding unnecessary data collection.

FastDAQ events appear as clickable dots on PowerInsight dashboard - click a dot to view detailed event information. In this example, blue dots are “Sequence Change” events, and yellow dots are “RF State Start” events.

FastDAQ events appear as clickable dots on PowerInsight dashboard - click a dot to view detailed event information. In this example, blue dots are “Sequence Change” events, and yellow dots are “RF State Start” events.

Sample FastDAQ events captured by dynamic triggers that automatically adjust based on changing power conditions

Sample FastDAQ events captured by dynamic triggers that automatically adjust based on changing power conditions

These capabilities enable customers to capture all critical moments in the process while filtering out irrelevant idle-time data. In the example with eVerest, it allows users to monitor pulse timing under different power conditions and potentially leverage the data to optimize process performance at the wafer level.

Unlock the Future of Predictive Maintenance – Starting Today

The rich data logs captured by PowerInsight lay the foundation for advanced monitoring methods – combining domain expertise and data science to assess unit health in the field.

To prove what’s possible, our data science team developed a preliminary “Go / No-Go” model using machine learning techniques and years of AE Global Service RMA data. The model categorizes the match unit under test as either a probable NPO, as in “Go” status; or in need of service, as in “No-Go” status. This exemplifies AE’s broader strategy to develop comprehensive health monitoring and predictive models across all plasma power products.

To reach its full potential, the final model requires both real-time and historical data on plasma power products for continuously monitoring and accurate health assessments. PowerInsight offers a turn-key solution to begin building this high-quality dataset today – accelerating the path toward predictive maintenance and more efficient operations.

Summary

PowerInsight by Advanced Energy offers several key features that address challenges in semiconductor fabrication:

- Multi-source data integration and visualization – seamless comparison and trend analysis.

- Onboard oscilloscope-level captures and records FastDAQ events.

- Historical complementary data – time-stamped details on faults and warnings, unit statistics, and internal sensor data.

- Web-based access to months of data, available locally or remotely under the customer’s own secured network, and with no need to install any software.

- Configurable raw data export and backup.

- Scalable infrastructure for future predictive maintenance (PdM): Designed to evolve as more data becomes available, supporting continuous improvement in unit diagnostics.

PowerInsight has helped customers save millions by enabling faster root cause analysis and smarter maintenance decisions. Ready to accelerate your diagnostics?

To learn more about PowerInsight by Advanced Energy, visit: PowerInsight | Advanced Energy.

Jing Li

Advanced Energy

Jing Li is the Business Development Manager for PowerInsight by Advanced Energy®, leading solutions that leverage big data and domain expertise to optimize equipment performance and operational efficiency. She holds a Master’s in Engineering from University of Science and Technology Beijing and an MBA from University of Southern California. She brings global experience in product strategy, engineering, and customer engagement across industrial applications.

More posts by Jing Li