The Hazards of Pathogens and Risk-based Preventative Temperature Control

Veröffentlicht Dezember 01, 2016 von Advanced Energy Editor

Temperature Measurement in Food Processing

The relationship between food processing, temperature, and the hazard of pathogens is well documented. Quality control personnel can meet the risk-based preventive control for this hazard by measuring temperatures at critical in-plant control points. However, if proper care is not taken, even the measurement equipment and process can introduce hazards.

Temperature Tool Hazards

Although not specifically required in FSMA regulations, FSMA rules are sprinkled with references to maintaining electronic records. Written records are included as an option as well. Unfortunately, paper and pencil temperature data collection introduces an additional source of potential pathogen contamination. For example, dropping the pencil or clipboard during measurement could introduce contamination to the food being processed. In addition, time-consuming data acquisition and recording on fast moving processing lines introduces the potential for data entry errors.

Unfortunately, poorly designed automated temperature solutions may also cause problems. Many typical thermometer case designs may be awkward to handle and can accumulate grease, dirt, or other residues. The FSMA regulations require clean equipment.

Alternative Temperature Data Collection Tools

One of the best alternatives to pen-and-pencil data management is an automated temperature measurement solution purpose-built for use in food processing. In-plant process temperature measurement acquisition requires accuracy, speed, and cleanliness. Such an automated solution complies with the most demanding design requirements including a rugged design that withstands drops, shock, vibration, and frequent wash-downs. As a result, it operates reliably over long periods in harsh environments. Operationally, it is also very helpful to quality control personnel if it displays statistical data in real-time.

An automated data capture and storage solution eliminates error-prone paper-and-pencil recording of data. In the ideal situation, the operator simply inserts the probe, while the data logging thermometer automatically captures and records the time-stamped measurements. To facilitate data analysis and reporting, the thermometer then transmits results to either a local cloud server or vendor-neutral cloud storage via built-in wireless connectivity such as Bluetooth.

Although FSMA rules make multiple references to maintaining electronic records, they are not currently mandated. Written records are still included as an option. That said, FSMA requires that facilities be able to access HARPC records within 24 hours, which can be a problem for paper-based systems. Electronic data storage, with appropriate data set identification, can greatly accelerate record access and reporting.

HARPC For Preventative Controls

HARPC hazards analysis requires food processors to implement preventive controls to “provide assurances that any hazards requiring preventive control will be significantly minimized or prevented…” The occurrence of foodborne illnesses drove the FDA’s development of FSMA. As evidence of this concern, “process controls” is the first item listed under the preventive controls section (§117.135) and is defined as follows:

“Process controls include procedures, practices, and processes to ensure the control of parameters during operations such as heat processing, acidifying, irradiating, and refrigerating foods. Process controls must include, as appropriate to the nature of the applicable control and its role in the facility’s food safety system:

(i) Parameters associated with the control of the hazard; and

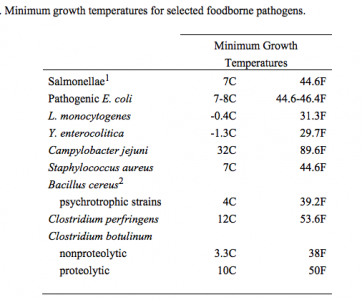

According to The Emerging Pathogens Institute at the University of Florida, the minimum growth temperatures for the most common foodborne pathogens has been well-established in scientific studies as shown in the table below.

Going one step further, the following chart ranks the disease burden caused by the most common foodborne pathogens. The rankings are based on the illness’s impact on quality of life plus the costs of the illness.

For further information, please reach-out to us today.