Scenarios: Infrared or Contact Thermometers

Veröffentlicht Januar 30, 2019 von Advanced Energy Editor

This post is Part 2 in a two part series regarding Contact vs. Non-Contact Thermometry and “How Infrared is Used for Temperature Measurement”. Click HERE for Part 1.

What is Infrared?

How is Infrared Used for Temperature Measurement?

Scenarios to watch out for:

For all applications, remember that an infrared non-contact measurement is only a surface measurement, not an internal temperature, so the core temperature of a food product cannot be measured using infrared.

Environmental conditions such as moving air, stray radiation or changes in the surface can affect the readings.

You can not measure through a glass window. The IR thermometer will measure the surface of the glass, not what is behind it.

Grills are very difficult because of changing surface conditions.

- Iron (and most metals) change their emissivity as they heat up, so you should set the emissivity very near the operating temperatures.

- Film on the cooking surface (oil, water, etc.) will also greatly change the emissivity.

Again, set your emissivity as near to the operating conditions as possible.

Infrared is not to be used to measure open grills that show flame or charcoal through the cooking surface.

More Considerations

Always be aware of your spot size and what is in it; the IR gun will average all the temperatures in its field of view.

EXAMPLE: when measuring a hot plate that is 2” smaller than the field of view, a portion of the background temperature reading will be averaged in and the reading will not be accurate.

Particles in the atmosphere like smoke, confetti, dust, can also cause errors in readings.

Remember that the infrared sensor is a thermopile and as such the instrument has to make an ambient reading to make the proper cold junction compensation adjustments. Always allow time for the instrument to normalize its temperature with the ambient temperature (i.e. If using the IR gun in a refrigerator, put the gun in for approximately five minutes before going in to take readings).

When used properly and in suitable environments/applications, non-contact infrared thermometers will give excellent repeatable measurements.

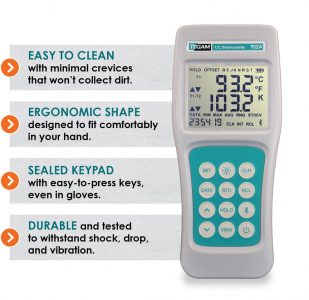

When your environment or application is not conducive to using infrared technology, TEGAM offers a complete line of contact thermometers. View them HERE.

.jpg?lang=en-US)