Enhancing Yield in Semiconductor Epitaxy with Advanced Power and Temperature Control

Veröffentlicht November 24, 2025 von Andreas Breitkopf

Blog Summary:

- Precision control is critical for semiconductor epitaxy: High-temperature processes like epitaxy require millisecond-level temperature control to avoid defects, ensure uniformity and maintain yield. Even minor deviations can lead to catastrophic losses, especially as the semiconductor industry moves to Angstrom Era geometries.

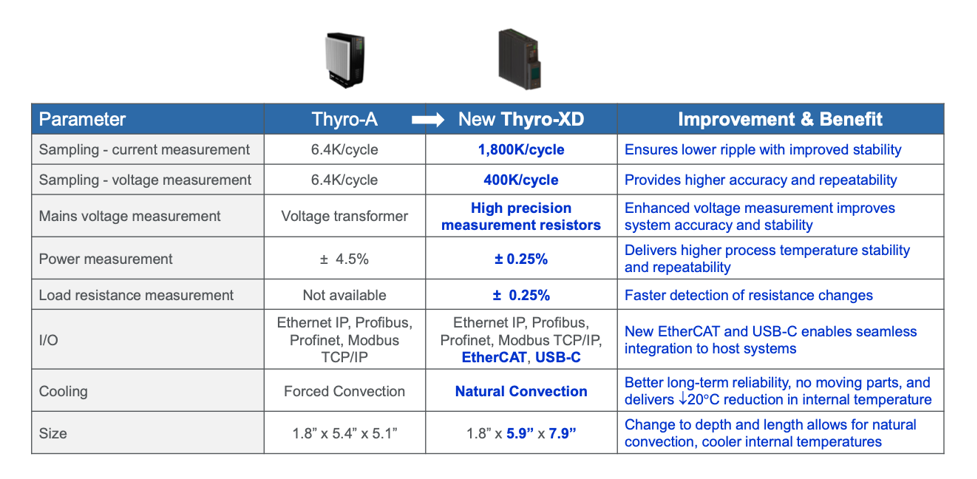

- Advanced Energy’s Thyro-XD™ SCR power controllers deliver breakthrough accuracy: The latest generation of SCR controllers achieves a tenfold improvement in accuracy (from ±4.5% to ±0.25%), faster response times, and minimal power ripple. These advancements enable highly stable and repeatable thermal management in dynamic, high-temperature environments.

- Integrated solutions enhance real-time control and reliability: Features like the Advanced Bus Module (ABM) for pyrometer integration, fanless design for long-term reliability, and support for modern communication protocols (EtherCAT, USB-C, etc.) make Thyro-XD ideal for semiconductor epitaxy and other industrial applications requiring precise thermal control.

Precision control is essential to maximize quality and yield in high-temperature manufacturing processes. In semiconductor epitaxy, failing to accurately measure and promptly respond to changes may result in crystal quality degradation, ultimately affecting reliability, performance, and yield.

This blog explores how the shift to advanced electrical heating and the invention of rapid-response Silicon Controlled Rectifier (SCR) power controllers enables these improvements in semiconductor epitaxy. Specifically, Advanced Energy’s latest generation of SCR power controllers (Thyro-XD™) were developed to deliver the industry’s highest accuracy (10X improvement from ±4.5% to ±0.25%), repeatability and fastest response time in highly dynamic high-temperature manufacturing processes. SCRs are ideal for semiconductor lamp-heated epitaxy processes and for steel, glass manufacturing, and a range of high-temperature industrial applications.

Semiconductor Epitaxy

In semiconductor manufacturing, epitaxy – the process of growing a crystalline layer upon a crystalline substrate – is among the most temperature-sensitive steps.

Processes such as metal-organic chemical vapor deposition (MOCVD) and lamp-heated rapid thermal processing (RTP) require heating the substrate to temperatures exceeding 1,000oC. This heating process must be performed with incredible speed and exceptional levels of uniformity.

During this process, the wafer is placed on a graphite susceptor inside a reactor chamber. This is then heated, with gas precursors introduced to react with the hot surface on the wafer to deposit the desired atomic layer(s).

The goal is to create a perfect, defect-free crystal lattice. The entire process hinges on the precise control of temperature in the chamber. Whether incorrect temperature or a temperature gradient, getting it wrong can lead to stacking faults and thin film point defects with non-uniform doping and poor performance in the manufactured device. This can be catastrophic for any electronic device, and, as we move to Angstrom Era geometries, it can become disastrous to yield.

Thermal Management in Epitaxy

SCR power modules can be used for other industrial thermal processes such as steel and glass making, however when it comes to semiconductor epitaxy, there is one very significant difference. Unlike an arc furnace, which has a large volume of molten material, an epitaxial reactor has a very low thermal mass. The temperature in the chamber can therefore change incredibly quickly.

To ensure a uniform, (ideally) defect-free wafer, tungsten-halogen lamps or resistive graphite heating elements must be controlled with millisecond precision to achieve complex recipe steps. The chambers need to perfectly enact ramps up to a specific temperature - precise "soaks" where the temperature is held perfectly steady, and control down ramps.

Any deviation from the recipes will have immediate consequences. A lack of uniformity in temperature across the wafer can lead to variations in layer thickness and chemical composition. Overshooting on temperature can damage the delicate crystal structure while undershooting can result in incomplete chemical reactions and poor film quality.

Precise power control is essential, as fluctuations in power directly cause temperature oscillations on the wafer surface. To ensure stability, power delivery requires minimal voltage or power ripple. SCRs are commonly used to achieve this, but they have had to adapt over time. The transition to Angstrom Era geometries is now driving yet another phase of evolution for these systems.

This is particularly significant, as a single failed production wafer can result in tens of thousands of dollars in lost revenue. With billions at stake in manufacturing sub- and near-sub nanometer geometries, losing a pre-production test wafer can incur costs well into the six-figure range.

.png) Figure 1: Advanced Energy’s Thyro-XD module delivers the industry’s highest accuracy and fastest response time in highly dynamic high-temperature manufacturing processes

Figure 1: Advanced Energy’s Thyro-XD module delivers the industry’s highest accuracy and fastest response time in highly dynamic high-temperature manufacturing processes

The Thyro-XD SCR power controller and Advanced Bus Module (ABM)

To achieve effective process control, most solutions have relied on temperature controllers to ensure system compatibility. For instance, Advanced Energy’s new range of Thyro-XD™ SCR power controllers, designed to work with optical pyrometers, offer enhanced precision in fast-ramping, high-temperature manufacturing processes.

Advanced Energy (AE) launched its Advanced Bus Module (ABM) that enables engineers to couple multiple AE Impac® measurement pyrometers to SCR solutions for more precise real-time temperature control. The unit has RS-485 connectivity and can be networked into a wider system via a Thyro Anybus® module.

The ABM can accommodate host connections at distances up to 30 m while providing an EtherCAT gateway and supporting EtherCAT FoE upgrades.

Advanced Energy’s new Thyro-XD SCR power controller can deliver 15 kW at up to 30 A and offers several accuracy-related advances over earlier solutions. It features a power density of 188 W/in3, is optimized for semiconductor tools, and doubles the control capacity versus other available products.

The sampling rates for current and voltage are significantly increased, thereby improving stability, accuracy and repeatability while reducing ripple. Additionally, the voltage transformer is replaced by high precision measurement resistors, further enhancing accuracy and stability. In the Thyro-XD, the output power ripple measured without averaging is just ±8 W (2-15 kW), a ten-fold improvement on previous products.

Improving the power measurement from ±4.5% to just ±0.25% is a huge leap forward to deliver higher process temperature stability and repeatability. In addition, a new load resistance measurement enables faster detection of resistance changes, which helps prevent potential damage to resistors and reduces maintenance.

One of the key advancements in the Thyro-XD compared to previous controllers is its fanless design. Unlike earlier models that relied on a cooling fan, the Thyro-XD is engineered and rigorously tested to operate without any active cooling components (in other words, it is designed for natural convection cooling). By eliminating the sole moving part—the fan—this design significantly enhances long-term reliability and reduces risk.

Like the Thyro-A, the Thyro-XD supports Ethernet IP, Profibus, Profinet, and MODBUS TCP/IP input-output protocols. Additionally, it incorporates EtherCAT and USB-C, ensuring enhanced compatibility with contemporary systems.

Conclusion

Precise power and temperature control are critical for maximizing yield and maintaining quality in semiconductor epitaxy processes. Advanced Energy's innovative Thyro-XD SCR power controllers and ABM deliver unparalleled accuracy and responsiveness, meeting the demands of dynamic, high-temperature manufacturing environments. By addressing the challenges posed by transitioning to Angstrom Era geometries, these solutions help mitigate costly production losses and ensure faultless results. With superior efficiency, robustness and compatibility, these advancements represent a significant leap forward in semiconductor manufacturing technology. For detailed specifications and insights, explore the product documentation provided on our web pages.

Data sheets and further information on the products mentioned in this blog can be found on the Thyro-XD SCR Power Controller and the Advanced Bus Module (ABM) web pages.

Andreas Breitkopf

Advanced Energy

Andreas Breitkopf currently serves as Senior Director, Marketing-Demand Generation, Critical Sensing and Control, within Advanced Energy’s System Power business.

Mehr Beiträge von Andreas Breitkopf

durchsuchen

Kategorien A-Z

Tragen Sie sich in unsere Mailingliste ein

Abonnieren

Neueste Beiträge

View on X