ThermalSpection Series

Real-time, Continuos, and Automated Fault Detection and Monitoring of Critical Vessels

특징

- Automated thermal monitoring for performance and safety

- Continuous monitoring without personnel constraints

- Early and remote fault detection

- Automatic hot-spot tracking

- HTML visualization displays for broadcast on plant intranet

- Automated analysis with built-in industry-standard analytics

- OPC/Modbus interface

- Optional integration with OSIsoft’s PI database system

혜택

- Replace error-prone manual inspection with automated monitoring

- Identify transient thermal events not detectable with manual inspection

- Integrate with existing control systems via standard protocols

- Monitor assets after installation/maintenance to identify risk for infant mortality or faults

- Reduce risk and unplanned outages

- Utilize advanced features in a user-friendly interface

- Capture thermal data snapshot frames at set intervals or trigger using temperature alarms

- Easily integrate into existing plant DCS and data historian

사양

| 작동 온도 범위(°C): | -40 to 60 |

|---|---|

| 파장 범위(nm): | 8000-14000 |

| 광학 인터페이스: | 75 mm autofocus, others manual |

| 채널 수: | 2 |

| 정확도: | ±2 deg C or 2% of reading |

| 측정 속도(Hz): | 9 Hz, 50 Hz |

| 시야각: | 8° to 77° |

| 필터(µm): | 8 to 14 |

액세서리

Mikron LumaSpec Offline Analyzer 5.0

Advanced Thermal Image Processing, Analysis, and Report-Writing Software

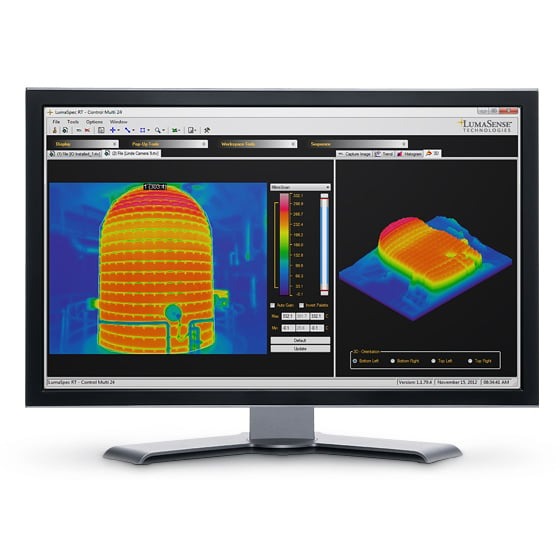

Mikron LumaSpec RT Software

Windows-Based, Real-Time Data Acquisition Software

기술 문서

기술 동영상

Monitoring Critical Vessels with ThermalSpection CVM

관련 애플리케이션

모든 애플리케이션 살펴보기서비스

Calibration and Alignment

Advanced Energy has the tools and processes to ensure your equipment continues to meet its original specifications. Our products are calibrated at global AE service sites with proprietary technology designed to exceed industry standards.

Repair

Our worldwide service centers provide fast cycle times, use only AE-qualified parts, and follow the original product's specifications and test procedures for the highest quality repair or calibration.