Optimizing the Power Grid: Fiber Optic Sensors Safeguard Transformers

게시됨 6월 02, 2025 으로 Alex Shewell

If there were any doubts about the necessity to monitor the temperature of substation transformers, recent events have highlighted their critical importance. A significant fire in a transformer on the outskirts of London resulted in 60,000 homes losing power and led to the closure of Heathrow, Europe’s busiest airport, causing over 1,000 flight cancellations and widespread inconvenience to hundreds of thousands of passengers.

As the world endeavors to reduce carbon emissions, electrical energy is becoming increasingly pivotal. Central to the global electrical supply is the grid, which operates by transmitting electricity from the generation point to the point of consumption.

At the heart of the grid are power transformers needed to step voltages up and down across the grid. Ensuring safe operation of these transformers requires constant monitoring of their internal winding temperature. The high-voltage environment, which makes conventional sensors impractical, alongside liquid oil cooling that surrounds the transformers, makes it challenging to directly measure a transformer’s winding temperature.

A widely adopted solution is FluorOptic® Temperature (FOT) measurement technology. This technology is immune to all forms of electromagnetic interference (EMI) and is capable of functioning safely and accurately inside a high voltage power transformer.

Principles of FOT Sensing

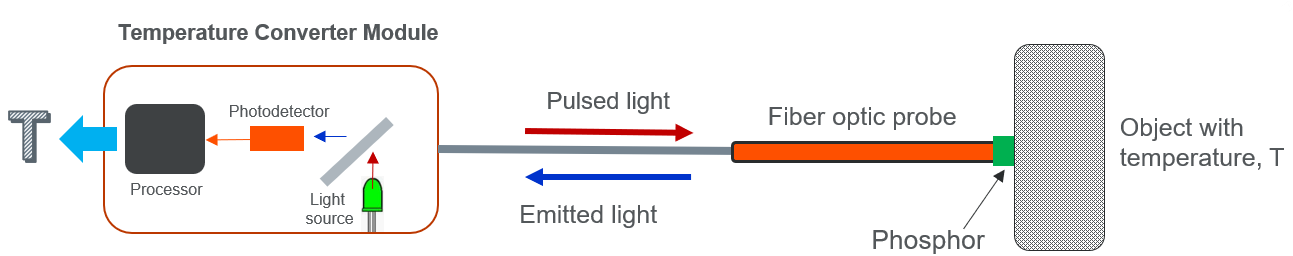

FluorOptic or Fiber Optic Temperature (FOT) technology operates by placing the sensing tip in direct contact with the measured object, similar to a thermocouple. However, instead of relying on an electrical voltage change, FOT utilizes light and the principle of phosphorescence to measure temperature.

Phosphor, a material known for its ability to "glow in the dark" when exposed to light, is integral to this technology. One early application of phosphors was the illumination of hands or dials on analog watches, enabling time to be read at night.

Upon exposure to a light source, phosphor accumulates light energy. Once the light source is removed, the material emits the stored energy for a brief duration until it is depleted. This emission period is referred to as the 'decay time,' and its duration is highly sensitive to the phosphor's temperature. This temperature-dependent decay time forms the foundational principle upon which FOT technology operates.

As the world endeavors to reduce carbon emissions, electrical energy is becoming increasingly pivotal. Central to the global electrical supply is the grid, which operates by transmitting electricity from the generation point to the point of consumption.

At the heart of the grid are power transformers needed to step voltages up and down across the grid. Ensuring safe operation of these transformers requires constant monitoring of their internal winding temperature. The high-voltage environment, which makes conventional sensors impractical, alongside liquid oil cooling that surrounds the transformers, makes it challenging to directly measure a transformer’s winding temperature.

A widely adopted solution is FluorOptic® Temperature (FOT) measurement technology. This technology is immune to all forms of electromagnetic interference (EMI) and is capable of functioning safely and accurately inside a high voltage power transformer.

Principles of FOT Sensing

FluorOptic or Fiber Optic Temperature (FOT) technology operates by placing the sensing tip in direct contact with the measured object, similar to a thermocouple. However, instead of relying on an electrical voltage change, FOT utilizes light and the principle of phosphorescence to measure temperature.

Phosphor, a material known for its ability to "glow in the dark" when exposed to light, is integral to this technology. One early application of phosphors was the illumination of hands or dials on analog watches, enabling time to be read at night.

Upon exposure to a light source, phosphor accumulates light energy. Once the light source is removed, the material emits the stored energy for a brief duration until it is depleted. This emission period is referred to as the 'decay time,' and its duration is highly sensitive to the phosphor's temperature. This temperature-dependent decay time forms the foundational principle upon which FOT technology operates.

Figure 1. Temperature Converter Module

Figure 1. Temperature Converter Module

The light emitted is not constant and follows a Tau decay where Tau is a measure of the rate of decay that is proportional to the temperature of the surface being measured.

Since FOT relies solely on light, it is entirely unaffected by EMI, which is incredibly important in substations where tens of kilovolts are being switched. It is also completely non-conductive, which is essential from a safety perspective.

The phosphor is made of inorganic ceramic, making it chemically inert and highly stable with no long-term drift. This stability eliminates the need for calibration, which can be costly and require system downtime. With sensor tips as small as 0.5 mm, they are minimally intrusive and do not significantly affect the temperature of the measured surface.

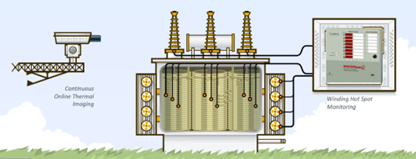

Advanced Energy’s FOT Technology for Transformer Monitoring

Directly measuring the temperature of transformer windings using conventional methods isn’t feasible, so winding temperature indicators (WTI) were developed to estimate the winding’s temperature. These WTI systems respond very slowly to load changes and are not as accurate as FOT sensors. As dynamic loading conditions on the grid become more common, the slow response time of WTIs can lead to poor information for grid operators. For example, direct winding measurement using FOT exposes that winding hot spots increase in temperature quickly after load changes whereas it can take many hours for this to be detected by WTIs.

Figure 2. Thermal Imaging and Monitoring

Figure 2. Thermal Imaging and Monitoring

Elevated temperatures impact the insulating material, dramatically accelerate the aging process of transformers. Should the temperature rise beyond 85°C, the insulating paper begins to deteriorate, with the aging rate doubling for every 6°C increment above this critical threshold. This is one reason keeping track of the winding hot spot (WHS) is of paramount importance and widely regarded as the single most crucial parameter in transformer loading.

As such, effective temperature monitoring is essential to safeguard valuable transformers. Accurate data allows for the optimized operation of cooling pumps and, when necessary, triggers protective shutdowns to avert catastrophic damage.

Advanced Energy offers a cutting-edge FOT converter platform, the Luxtron® M-1100. This innovation boasts an advanced light source and enhanced low-noise electronics, able to achieve a remarkable accuracy of better than 0.5°C. Enhanced by two groundbreaking proprietary phosphor formulations, VioLux™ and RubiLux™, the system ensures an outstanding accuracy, repeatability, and noise of 0.05°C across a wide measurement range of -200 to +450°C. When configured for transformer winding hot spot measurements, the measurement can be optimized to achieve peak accuracy for a temperature range of -30 to +200°C.

.jpg) Figure 3. Luxtron M-1100

Figure 3. Luxtron M-1100

Figure 4. Probe before installation showing the tip inserted in the spacer.

Figure 4. Probe before installation showing the tip inserted in the spacer.

Figure 5. Picture after the spacer with probe (in this picture two probes are installed into a single spacer) is inserted into the transformer winding.

Figure 5. Picture after the spacer with probe (in this picture two probes are installed into a single spacer) is inserted into the transformer winding.

The complete measurement system often includes sensor extension cables and leak-proof sealed tank wall feedthroughs, which are also supplied by Advanced Energy.

As electricity becomes an increasingly valuable resource, protecting generation and delivery infrastructure from degradation and failure is crucial. FOT is a reliable and robust measurement technology that safeguards these assets through precise temperature monitoring for cooling control and protective shutdown. By effectively monitoring WHS, a transformer’s lifespan can extend significantly, resulting in substantial long-term cost savings.

For more information on Advaned Energy’s FOT products, visit: Fiber Optic Sensors | Advanced Energy and check out AE’s latest Advancing Energy Podcast on YouTube featuring the M-1100 here.

All About Fiber Optic Thermometry

5월 29, 2025

Advanced Energy's Alex Shewell, moderated by Johannah Knudson, discusses fiber optic thermometry, use cases, applications (such as semiconductor, medical and power systems) and highlights Advanced Energy's FluorOptic® Thermometry (FOT) converter, the Luxtron® M-1100. The Advanced Energy's Luxtron M-1100 is the latest FluorOptic thermometry (FOT) converter platform, featuring an advanced light source and improved ultralow noise electronics. Benefits of the M-1100 include: non-contact measurement to minimize the thermal offset, easy to install into OEM equipment, achieve high accuracy and an extreme temperature control for different etching and wafer fab processes, and receive support from experienced applications engineers to customize probes for OEMs.

Close Popup

Alex Shewell

Advanced Energy

Alex Shewell is currently a Product Management Specialist for the FOT products at Advanced Energy. Prior to her current role, she worked in supply chain and logistics for the Advanced Energy Plasma Power products. She holds a B.S. in Physics from UT Austin and an M.S. in Materials Science from Colorado State University.

더 많은 게시물 Alex Shewell