Improving Large Area Sputtering Accuracy with Modern Pulsed and DC Power Systems – Powering a New Year

投稿 12月 18, 2025 によって Craig Rappe

Blog Summary:

In this post, you’ll learn how Ascent® DC and Pulsed-DC Systems:

• Deliver higher deposition rates and faster arc response with advanced waveform control.

• Enable modular, scalable upgrades that fit seamlessly into existing legacy Crystal cabinet footprints.

• Enhance process stability with cutting-edge arc management and dual magnetron control.

• Offer real-time diagnostics and process monitoring through PowerInsight by Advanced Energy® software for smarter, data-driven operations.

• Increase your glass factory tool up time with power upgrades.

In this post, you’ll learn how Ascent® DC and Pulsed-DC Systems:

• Deliver higher deposition rates and faster arc response with advanced waveform control.

• Enable modular, scalable upgrades that fit seamlessly into existing legacy Crystal cabinet footprints.

• Enhance process stability with cutting-edge arc management and dual magnetron control.

• Offer real-time diagnostics and process monitoring through PowerInsight by Advanced Energy® software for smarter, data-driven operations.

• Increase your glass factory tool up time with power upgrades.

For several decades, Advanced Energy’s Crystal family of low-frequency AC power supplies set the standard for large-area glass coating applications. However, as processes are now requiring more precise control with faster communications, it is time to replace Crystals with Advanced Energy’s Ascent product family.

The Ascent family of pulsed and DC power systems deliver greater efficiency and more precise arc management. They provide advanced monitoring capabilities, as well as modularity and scalability, to give customers extra flexibility. Advanced Energy (AE) equips thin film manufacturers with the next wave of advanced power solutions to enable new and exciting products across sectors like automotive, medical, industrial, smart-home, and consumer electronics.

The Need for Greater Precision

AE’s newest Ascent solutions have been critical in optimizing properties and performance for a wide range of glass coating applications.

Good examples of this can be seen in the differences between specialized glass coatings like triple-glazed windows (engineered for heat retention), solar panels (for on-glass electrical terminations and high optical transmission), and various automotive glass applications (for anti-glare, anti-reflection, defogging, de-icing, UV protection, privacy, and for features like heads-up displays).

To achieve these features, specific conductive and dielectric materials are used, with notable examples including indium-tin oxide (ITO) and aluminum-doped zinc oxide (AZO) for front electrodes; molybdenum (Mo) for rear contacts; titanium dioxide (TiO2) for reflection management; and aluminum (III) oxide (Al2O3) to give durability and scratch resistance.

Dual magnetron sputtering (DMS) is used in the sputtering process for depositing the required ultra-thin films on glass, with deposition rates up to two microns per minute. Large-area coating processes for products such as flat-panel displays and architectural glass require high power systems. Higher target power density can lead to arcing, uneven layers, and the release of large (up to 10 microns) particulates from the target electrode. Given that coatings are often required to be one micron thick (or thinner), these sputtering process issues can significantly compromise quality and careful power control. Legacy systems, such as Crystal, struggle to deliver the required precision demanded for today’s advanced applications.

Figure 1: Ascent and Ascent DMS units powering cathode pairs for deposition.

Figure 1: Ascent and Ascent DMS units powering cathode pairs for deposition.

Reshaping the Power Distribution Architecture

Ascent implements several advances to deliver a greater level of control. This begins with Advanced Energy’s cutting-edge Arc Management System™ (AMS) technology through its AC-DC modules, which provide a high-voltage DC bus to power separate DMS accessories. The DMS units support 5-95% duty cycles allowing for power regulation to each cathode in the magnetron, giving extra flexibility like co-sputtering. In addition, Advanced Energy developed creative approaches for enhanced stability and faster control.

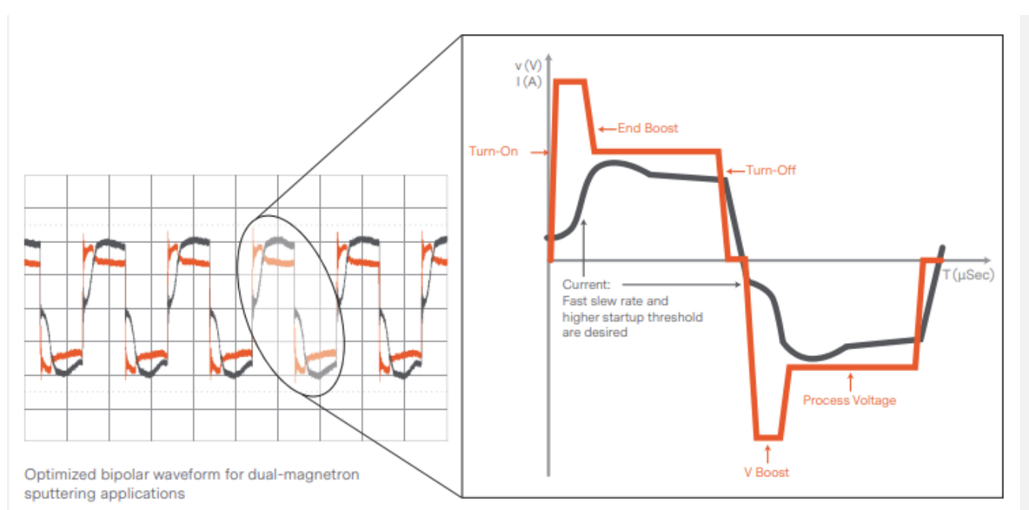

A second significant change is the move from a sinewave output to a bipolar pulsed square-wave. By using a pulse frequency that is adjustable up to 50 kHz, and waveform shaping that delivers an initial boost before applying a constant process voltage, Ascent power supply units enable 8 to 10% higher deposition rate and faster arc response.

Figure 2: Ascent DMS utilizes bipolar square wave format for a more constant process voltage and higher quality deposition.

Figure 2: Ascent DMS utilizes bipolar square wave format for a more constant process voltage and higher quality deposition.

Advanced Energy has also created the unique Arc Sync® and Set Point Compensation™ technologies, which enable progressive arc management and enhanced flexibility. The Ascent family also includes Pulse Sync control, which permits closer cathode placement to maximize plasma density in multi-cathode magnetrons.

In contrast to the monolithic architecture like Crystal, the modularity of Ascent eases system scaling and makes it easy to fit into an existing Crystal cabinet footprint of comparable power rating, allowing companies to upgrade to the new technology with minimal disruption.

Latest Ascent Innovations

The latest solutions in the Ascent family are the AMS II and Ascent AP Pulsed and DC power systems. The Ascent AMS II features full water cooling and a single, expanded operating area, while the Ascent AP features higher frequency up to 150kHz. The Ascent product line enables Advanced Energy’s patented dynamic reverse pulsing (DRP) for higher deposition rates at lower process temperatures and reduced film stress. They also feature today’s most advanced control, pulse shaping, and diagnostics for precision deposition and superior process productivity.

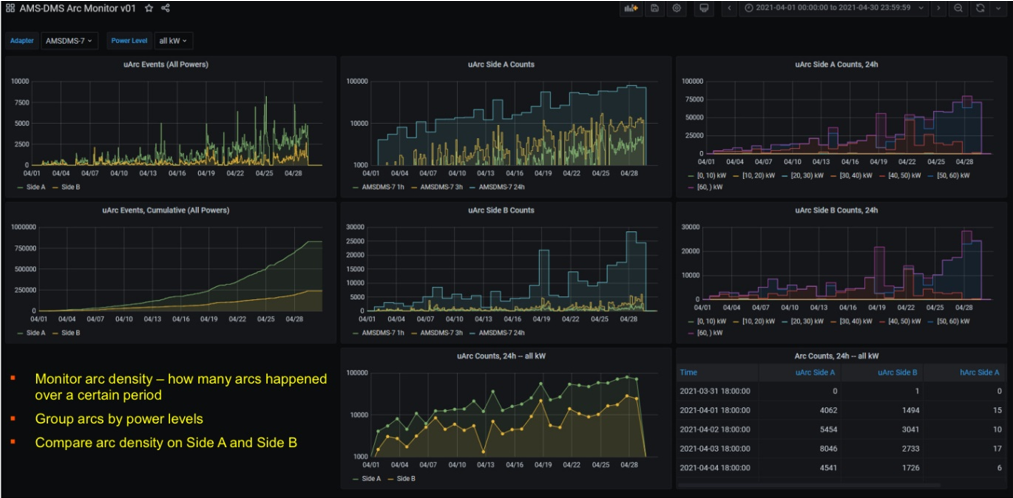

Both Ascent AMS II and Ascent AP systems integrate AE’s PowerInsight by Advanced Energy®, delivering advanced process monitoring and troubleshooting capabilities. Users can securely share data across the factory network, customize dashboards to set alerts for anomalies, track multiple power supplies, and monitor process status. PowerInsight provides data-driven insights such as arc parameters, generator statistics, firmware versions, and warning flags. Additionally, PowerInsight can read data from PLCs via OPC-UA, enabling correlation analysis between power supply performance and other process variables in industrial applications.

Figure 3: The PowerInsight data dashboard is highly customizable to monitor target units and apply filters to the raw data. This example dashboard is set up to monitor arc counts and to show the trends of arc density and imbalance between side A and side B.

Figure 3: The PowerInsight data dashboard is highly customizable to monitor target units and apply filters to the raw data. This example dashboard is set up to monitor arc counts and to show the trends of arc density and imbalance between side A and side B.

For further information and to replace installed legacy Crystals, visit Ascent systems and PowerInsight on the Advanced Energy website or contact your local Advanced Energy field applications engineer.

Additional Resources

A foundational article on large-area sputtering can also be found here.

Craig Rappe

Advanced Energy

Craig Rappe is a senior field applications engineer at Advanced Energy. He has been in the PVD industry for more than 25 years, serving in various roles. His focus is providing advanced power solutions to application and process challenges as well as educating the next generation on “electron management” as often as possible.

その他の投稿 Craig Rappe