Improving Thin Film Quality: Advanced Pyrometry Solutions for Precise Vacuum Chamber Temperature Monitoring

已发布 十月 27, 2025 由 Tim Dubbs

Blog Summary

• Vacuum deposition and temperature control: Depositing materials in a vacuum minimizes contamination and ensures precise delivery to the substrate, which is critical for producing high-quality thin films and coatings. Accurate temperature measurement and control during this process are essential to maintain coating quality, uniformity and adhesion.

• Pyrometer selection and emissivity considerations: Pyrometers measure temperature by detecting infrared radiation. Choosing the right pyrometer involves understanding the material’s emissivity, the environment and the required wavelength. Ratio pyrometers can overcome emissivity challenges by comparing readings at two wavelengths, improving accuracy even in changing conditions.

• Accessing vacuum chambers with pyrometers: There are three main methods for integrating pyrometers into vacuum chambers: lens-based systems, light-pipe optics and fiber optic pyrometers. Each has advantages depending on temperature range, contamination risk and chamber design. Advanced Energy pyrometers like the Impac® ISR 6 and Mikron® Photrix™ series offer high-speed, accurate measurements with flexible mounting options for industrial applications.

• Vacuum deposition and temperature control: Depositing materials in a vacuum minimizes contamination and ensures precise delivery to the substrate, which is critical for producing high-quality thin films and coatings. Accurate temperature measurement and control during this process are essential to maintain coating quality, uniformity and adhesion.

• Pyrometer selection and emissivity considerations: Pyrometers measure temperature by detecting infrared radiation. Choosing the right pyrometer involves understanding the material’s emissivity, the environment and the required wavelength. Ratio pyrometers can overcome emissivity challenges by comparing readings at two wavelengths, improving accuracy even in changing conditions.

• Accessing vacuum chambers with pyrometers: There are three main methods for integrating pyrometers into vacuum chambers: lens-based systems, light-pipe optics and fiber optic pyrometers. Each has advantages depending on temperature range, contamination risk and chamber design. Advanced Energy pyrometers like the Impac® ISR 6 and Mikron® Photrix™ series offer high-speed, accurate measurements with flexible mounting options for industrial applications.

Depositing materials in a vacuum environment reduces contamination and enables materials to travel unimpeded to the substrate. As such, this technique is an important industrial process for creating thin films and coatings across a diverse range of applications including semiconductor manufacturing, optics or glass and beyond.

Accurate temperature measurement and control are essential during the deposition phases as this directly affects the quality, uniformity, adhesion and properties of the deposited film or coating. Without precision measurement and control, the quality and reliability of coatings can suffer from yield loss and quality impacts.

A commonly used instrument for measuring industrial temperature is a pyrometer. Multiple types are available, and expertise is required to select the optimal instrument for a given application and to mount it correctly in the chamber.

Pyrometers and infrared radiation

Selecting the best pyrometer requires an understanding of the target application. Both the material properties of the object to be measured and the environment will affect the collected infrared (IR) radiation and impact measurement accuracy.

Pyrometers work by detecting the IR radiation that any object above absolute zero emits. The intensity (Wl) of this is dependent on temperature (T), wavelength (l) and the emissivity (el) of the object, with the relationship defined by Planck’s Blackbody equation.

Fig. 1: Planck’s Blackbody equation

Fig. 1: Planck’s Blackbody equation

Emissivity, which is a measure of how effectively a material emits IR radiation versus an ideal blackbody at the same temperature, is crucial. Factors such as the material, surface condition and temperature of the material, as well as the wavelength and angle of the pyrometer, will all impact emissivity.

As objects become hotter, they emit more IR radiation. This is key to the selection of a pyrometer as, to enable accurate measurement, there must be sufficient IR energy in the wavelength(s) that the pyrometer is able to measure. Often a bandpass filter will be used within the pyrometer to ensure only the wavelength of interest is observed.

The material being deposited can coat windows and lenses, so this similarly has an impact on the choice of mounting technique. To ensure accurate low-temperature readings, it's sometimes necessary to choose a specific pyrometer detector wavelength to avoid contamination. Alternatively, heated windows or purge systems can be used to reduce contamination.

Selecting the correct pyrometer

When selecting a pyrometer, it is important to select detector wavelength and temperature range to match the intended application. Other factors such as measurement uncertainty, repeatability and optical performance (spot size or field of view) also merit consideration.

Not directly related to measurement, but still important, are the form factor and ambient conditions where the pyrometer operates. The communication interfaces, which need to be compatible with the wider system where the pyrometer will be used, are merit consideration.

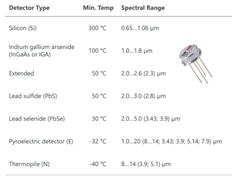

The wavelength (and therefore the minimum temperature that can be detected) is closely related to the material the detector is made from, as illustrated by the table below.

Fig. 2: The table shows approximate lower temperature range for detector type.

Fig. 2: The table shows approximate lower temperature range for detector type.

While it is vital to match the emissivity of the application, this should be achieved using the shortest wavelength possible to minimize uncertainty due to emissivity errors.

Finally, it is possible to implement digital ratio (aka ‘two color’) pyrometers in a system. These use two separate, adjacent wavelengths with temperature calculated as a ratio of the two detectors. This effectively removes emissivity from the equation, allowing temperature measurement even when emissivity is not known, or if it changes during the process – as it does during deposition. Unlike emissivity, the ratio of the readings is unaffected by the presence of dust or deposition material on the viewing window and so remains unaffected and accurate.

Fig. 3: An example of the Impac ISR 6 series of digital ratio (two-color) pyrometers.

Fig. 3: An example of the Impac ISR 6 series of digital ratio (two-color) pyrometers.

For high temperature applications, the Advanced Energy developed the Impac® ISR 6 series of digital ratio pyrometers, which can measure temperature over four ranges between 600°C and 3,000°C with a fast, 2 millisecond (ms) response time. Spectral range covers 0.9 µm to 1.05 µm and the units are housed in a robust stainless-steel enclosure with high-quality optics that can be manually focused for use in harsh industrial applications.

Accessing the vacuum chamber for pyrometers

There are three core options for accessing a vacuum chamber with a pyrometer. Lens-based devices (such as the ISR 6) have a converging lens that concentrates the IR collected energy from a small spot. This is a flexible, low-cost approach that allows for external mounting and simplicity of change. The pyrometer is also typically coupled with windows that can be made from quartz, sapphire, calcium fluoride (CaF2) or germanium. However, care must be taken to match the wavelength of the window material to that of the pyrometer otherwise the IR energy of interest may simply be blocked out. As the ISR 6 has a short wavelength, almost any window would be appropriate. But this is not the case for all pyrometers. For example, a lead selenide (PbSe) detector with a 4 µm detection wavelength would not work with a quartz window, which has a wavelength of sub-3 µm.

Where there is no window, or it is desirable to get close to the hot object, then light-pipe optics are preferred. These collect light well, allowing use with lower temperatures, and can reach difficult locations. In fact, a 300°C silicon detector pyrometer may be able to measure down to 250°C using a light pipe, due to its light-collecting ability.

Accessing the vacuum chamber for pyrometers

There are three core options for accessing a vacuum chamber with a pyrometer. Lens-based devices (such as the ISR 6) have a converging lens that concentrates the IR collected energy from a small spot. This is a flexible, low-cost approach that allows for external mounting and simplicity of change. The pyrometer is also typically coupled with windows that can be made from quartz, sapphire, calcium fluoride (CaF2) or germanium. However, care must be taken to match the wavelength of the window material to that of the pyrometer otherwise the IR energy of interest may simply be blocked out. As the ISR 6 has a short wavelength, almost any window would be appropriate. But this is not the case for all pyrometers. For example, a lead selenide (PbSe) detector with a 4 µm detection wavelength would not work with a quartz window, which has a wavelength of sub-3 µm.

Where there is no window, or it is desirable to get close to the hot object, then light-pipe optics are preferred. These collect light well, allowing use with lower temperatures, and can reach difficult locations. In fact, a 300°C silicon detector pyrometer may be able to measure down to 250°C using a light pipe, due to its light-collecting ability.

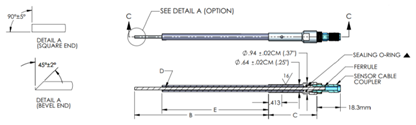

Fig. 4: Sample light pipe design showing adjustments for length and view angle.

Fig. 4: Sample light pipe design showing adjustments for length and view angle.

Light pipes are (typically) made of sapphire or quartz and are placed into the chamber via a vacuum feed-through. Length can vary (up to 400 mm), and the pipes can be bent to reach inaccessible places, with purges fitted where the application demands.

The final class, fiber optic pyrometers, combine the benefits of the two previous types – implementing a remote lens head, or light pipe – that allows the probe to be placed close to the hot material along with a fiber optic cable to extend through a port to the pyrometer electronics. This allows flexibility while keeping the sensitive electronics outside the harsh environment of the vacuum chamber.

Feed-throughs can be achieved via a sealed method (this requires the core size to be matched and is relatively expensive) or a compression method, which is a lower cost option. However, in this case cables must be set in epoxy to prevent vacuum leaks.

The final class, fiber optic pyrometers, combine the benefits of the two previous types – implementing a remote lens head, or light pipe – that allows the probe to be placed close to the hot material along with a fiber optic cable to extend through a port to the pyrometer electronics. This allows flexibility while keeping the sensitive electronics outside the harsh environment of the vacuum chamber.

Feed-throughs can be achieved via a sealed method (this requires the core size to be matched and is relatively expensive) or a compression method, which is a lower cost option. However, in this case cables must be set in epoxy to prevent vacuum leaks.

Fig. 5: Fiber feedthrough options: Top – flange mounted sealed bulkhead. Bottom – welded compression fitting.

Fig. 5: Fiber feedthrough options: Top – flange mounted sealed bulkhead. Bottom – welded compression fitting.

One of the most advanced pyrometers currently available for vacuum deposition applications is Advanced Energy’s Mikron® PhotrixTM series. Devices in this family offer a robust and flexible package that has been designed for ease of integration, with high-speed (1 ms) options able to operate either as a standalone device, or as part of an array with multiple units networked via a multi-channel interface module. Highly sensitive short wavelength, narrow bandwidth detectors reduce any effect of emissivity errors and improve measurement accuracy.

Fig. 6: Example of Mikron Photrix series of pyrometers.

Fig. 6: Example of Mikron Photrix series of pyrometers.

The series offers five spectral response options and gives the lowest temperature capability of any short-wavelength pyrometer. This technology can be used with any type of optics (lens, light-pipe or fiber optic) for ultimate flexibility.

For further information on the Mikron and Impac series of pyrometers, or Advanced Energy’s wider portfolio of sensing products, please visit special materials pyrometers or temperature sensing pages.

For more in-depth reading on this subject as well as news, products and application content, visit Advanced Energy’s pyrometry pages.

For further information on the Mikron and Impac series of pyrometers, or Advanced Energy’s wider portfolio of sensing products, please visit special materials pyrometers or temperature sensing pages.

For more in-depth reading on this subject as well as news, products and application content, visit Advanced Energy’s pyrometry pages.

Tim Dubbs

Advanced Energy

Tim Dubbs is Advanced Energy’s Director, Apps Engineering – Industrial Power, System Power.

更多文章 Tim Dubbs