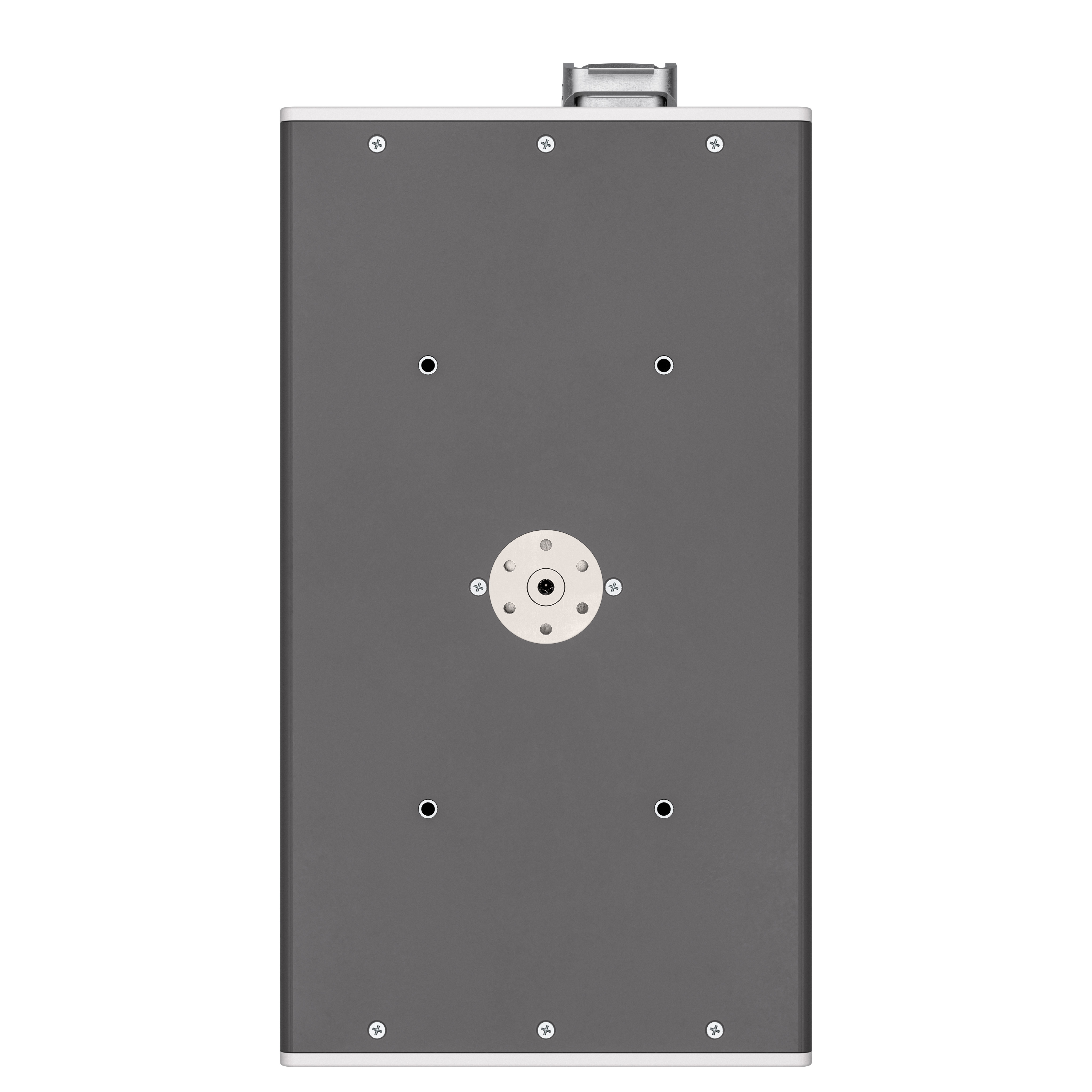

MAXstream Remote Plasma Source

Reliable, High-Performance Remote Plasma Source for Chamber Clean Applications

特点

- MAXstream 300 (≤ 3 L) for low flow applications and MAXstream 1200 (≤ 12 L) for higher flow applications

- Highly reliable RPS maximizes tool uptime

- Enhanced cooling of plasma source walls to reduce damage from thermal expansion and chemical erosion

- Active monitoring and control of plasma power for advanced power control

益处

- Optimize cost via multiple flow options

- Save valuable tool space with a smaller footprint than Xstream RPS

- Extremely reliable ignition with unique AE dual ignition cores

- Increase chamber life with proprietary AE chamber design

- Reduce cleaning time with up to 12 SLPM flow capabilities

规格

| 冷却: | Water |

|---|---|

| 输出频率(兆赫、千赫): | 400 kHz |

| 输入电压 (V): | 208 VAC |

| 功率等级(千瓦): | 6 to 12 kW |

| 机架宽度: | N/A, chamber mounted |

| 通信接口: | RS-232, Analog, Ethernet, EtherCAT |

| 流程应用: | Chamber Clean, Reactive Etch, Reactive Deposition |

| 化学兼容性: | Ar, O2, H2, N2, F2, H2O, NF3, CxFy |

Featured Resources

技术文档

技术视频

Chamber Cleaning with Advanced Energy Remote Plasma Sources

相关应用

探索所有应用服务

Premium Services

Combine services into a cost-effective plan including warranties, on-site visits, and more.

Repair

Our worldwide service centers provide fast cycle times, use only AE-qualified parts, and follow the original product's specifications and test procedures for the highest quality repair or calibration.

Calibration and Alignment

Advanced Energy has the tools and processes to ensure your equipment continues to meet its original specifications. Our products are calibrated at global AE service sites with proprietary technology designed to exceed industry standards.

Refurbishments

Choose refurbishment over repair to minimize down time, extend life, and reduce the total cost of ownership of your mature power products.

PowerInsight

Power your process with data using PowerInsight by Advanced Energy™, transforming data into actionable intelligence with advanced analytics and machine learning, enabling you to improve yield and reduce unplanned downtime.

.jpg)

.jpg?resizemode=force&maxsidesize=124)