Sekidenko OR4000T Series

Active

Multi-Channel, Non-Contact Optical Fiber Temperature Pyrometer with Configurable Wavelength Range and Fixed-Emissivity Correction

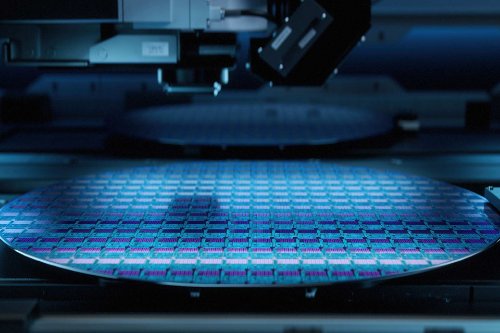

The Sekidenko OR4000T is a multi-channel, non-contact optical fiber temperature pyrometer that measures infrared energy being emitted from an object and converts it into usable temperature data (degrees °F or °C). Configure in a variety of measurement wavelengths based on target materials, process temperature ranges, and working distances from 3.9 in (100 mm) to 118.1 in (3000 mm). Available temperature ranges are: 122°F (50°C) to 2912°F (1600°C). Use up to four measurement channels with separate optical sensors connected by fiber optic cables.

特点

- In-situ, non-contact temperature measurement employing lensed optical sensors or sapphire light pipe sensors

- Industry-leading temperature and read rates

- Highly flexible, module-based platform architecture

- Full I/O and external trigger/synchronization suite

- Multiple wavelengths within one instrument

益处

- Improves temperature measurement accuracy for critical processes

- Enhances repeatability and minimizes variation

- Increases productivity, yield, and throughput

- Increases stability and reliability across multiple chambers and substrate materials

- Customizes to meet the functional and mechanical requirements of unique applications

规格

| 工作温度范围 (°C): | 50 to 3500 |

|---|---|

| 光谱范围(微米): | UV to 2300 |

| 接口/输出(毫安): | RS-232, RS-422/485, and Ethernet |

| 准确性: | ±1.5 °C |

| 重量(千克): | 2 |

| 波长重复性(pm): | ±0.1 |

技术文档

Product Information Documents

Miscellaneous

技术视频

Advanced Pyrometers: Enhancing Process Repeatability

11月 25, 2025

Discover how advanced pyrometers enhance thermal process repeatability and boost product quality in demanding industrial environments. This video highlights key features like active ambient compensation, immunity to contamination, robust designs for harsh conditions, and active emissivity compensation. Learn how these innovative temperature measurement tools ensure accuracy and reliability, overcoming challenges such as stray energy interference, changing emissivity, and extreme temperatures. Elevate your manufacturing processes with precision and innovation for superior performance!

Close Popup