Innovations in Power Conversion for Defense and Aerospace

已发布 六月 16, 2025 由 Todd Hendrix

Commercial power technologies meet demands for efficiency, performance, size, weight and reliability

Blog Summary

- Shift Toward Commercial Power Solutions in Defense and Aerospace: Historically, defense and aerospace sectors relied on custom-built power systems due to strict standards. However, budget constraints are now encouraging the adoption of commercial components.

- Efficiency, Size, and Performance Are Critical: Modern AC-DC and DC-DC power technologies are achieving higher efficiency and power density through innovations like single-stage PFC-regulation, wide bandgap semiconductors (SiC, GaN), and digital control systems. These advances reduce size, weight, and heat—key benefits for aerospace applications where space and thermal management are critical, as seen in systems like the F-35’s upgraded thermal management.

- Reliability and Customization for Harsh Environments: Defense and aerospace systems demand extreme reliability under harsh conditions. Companies like Advanced Energy (AE) are addressing this with ruggedized, configurable power solutions (e.g., Evergreen™ Vento, LCC1200, XF family) that meet military standards. AE products and services are commercial in nature and are not International Traffic in Arms Regulations (ITAR) compliant. AE also supports system integrity through advanced testing and calibration tools, ensuring clean, stable power and long-term performance.

Historically, strict standards in defense and aerospace led OEMs to create specialized power solutions. Now, budget constraints are driving the use of commercial components and sub-systems. As a result, the global market for military-grade commercial power products (which includes high-efficiency AC-DC power supplies, isolated DC-DC board mounted power and non-isolated point-of-load converters) is expected to grow from USD 2.7 billion in 2023 to almost USD 3.7 billion by 20301 .

Selecting standard, modified standard, and configurable products meets the power, performance, and resilience needs of mission-ready applications, minimizes development time and cost, and allows design teams to meet strict standards.

Performance, size and weight

The latest advances in AC-DC and DC-DC conversion technologies offer significantly improved efficiency and performance, such as highly integrated designs that combine power factor correction (PFC) with regulation in a single stage. This leads to lower losses than conventional multi-stage designs, reducing overall size, weight and complexity.

In aerospace platforms, these benefits translate directly to operational advantages, including enhanced fuel efficiency, extended aircraft range and endurance and optimized energy storage. Such factors are critical for high-performance systems like aircraft propulsion and satellite communications.

What’s more, increased efficiency also lowers heat dissipation, a particular challenge in defense and aerospace applications where space is at a premium and where reliability is mission-critical (increased operating temperatures have a direct correlation with increased component failures).

Fig. 1 The PTMS on the F-35 Lightning-II will cool off 80 kW of heat

Fig. 1 The PTMS on the F-35 Lightning-II will cool off 80 kW of heat

The importance of high-efficiency power electronics in this regard is illustrated by the power and thermal management system (PTMS) of the F-35 Lightning-II Joint Strike Fighter. Last year, the Pentagon announced it would be upgrading this on-board system and, in doing so, revealed the level of heat encountered during missions – especially in high-temperature locations such as the Middle East. The new benchmark, established by the F-35 Joint Program Office, aims to cool off 80 kW of heat from the aircraft’s subsystems, which will be significantly enabled by improvements in power conversion efficiency.

Increasing power density and efficiency to improve performance while saving space and weight is something common to multiple aerospace and defense designs. Advanced cooling techniques help achieve these goals, as well as the increased use of wide bandgap semiconductor materials such as silicon carbide (SiC) and gallium nitride (GaN) in the development of power supplies and power conversion products.

SiC and GaN semiconductors switch faster than silicon ones, enhancing performance and reducing the need for filtering and large passive components. Their superior thermal properties also decrease the need for cooling, allowing for smaller form factors.

At the same time, the integration of digital control systems in power electronics has enabled adaptive optimization techniques that adjust conversion parameters based on actual operating conditions. This helps enhance efficiency across the variable load profiles common in defense and aerospace applications.

Reliability

Whether part of a UAV flying at altitude over polar regions, an autonomous underwater vehicle, or a fighter jet undergoing training maneuvers in the Mojave Desert, electronic components used in defense and aerospace equipment need to withstand extreme temperature fluctuations, exposure to high levels of g-force, vibration and shock. This puts them under considerable strain, making reliability paramount.

In addition to the extended component operating life and improved performance at high temperatures that increased efficiency (and, thus, lower heat dissipation) enables, it is vital that critical systems and sensitive electronics receive clean and stable power. Precision AC-DC power supplies and high efficiency DC-DC converters are essential components for allowing these systems to support the safe and dependable operation of navigation systems, communication systems, and avionics.

Power technologies for defense and aerospace

Advanced Energy (AE) is at the forefront of developing innovative, dependable, resilient and cost-effective power technologies for commercial and defense and aerospace applications ranging from uncrewed and autonomous vehicles through radar, sonar and navigation systems to data processing and communications2.

The company’s power conversion solutions are specifically engineered to satisfy rigorous standards while providing the convenience of standard and modified parts that combine an extensive variety of power densities, output voltages and form factors that can be ruggedized to endure extreme conditions.

Some examples of the latest AC-DC developments for these markets include the Evergreen™ Vento family of air-cooled, high-power modules and the Excelsys XF family of configurable AC-DC power solutions.

Fig 2. Evergreen Vento

Fig 2. Evergreen Vento

Designed to deliver high-performance, optimized AC-DC conversion with fast system configuration for instant customization and power scaling, Evergreen Vento addresses the growing demand for high-power, high-efficiency, high-power-density bulk AC-DC power conversion. Offering 0.98 power factor for > 95% efficiency and a 38 W/in3 power density, this compact solution includes the 10 kW FCM10K air-cooled, hot swapable module in a 2 U x 3 U footprint and the 30 kW FCM30K shelf. By connecting multiple shelves together on an industry-standard 19” rack, defense and aerospace customers can meaningfully scale total system output to ultra-high-power levels.

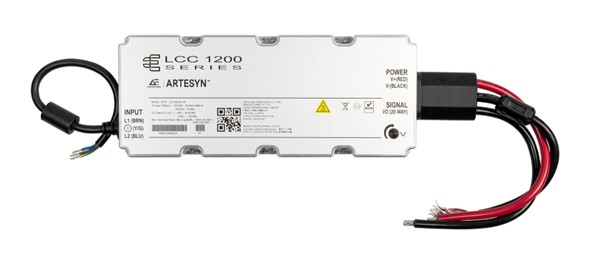

Fig 3. LCC1200 conduction cooled power supply

Fig 3. LCC1200 conduction cooled power supply

The LCC1200 is a fanless, environmentally sealed module that has been specifically designed for applications requiring high up-time. The unit can maintain its full 1,200 W load rating from -40 to 85 °C baseplate temperature without forced air and allows designers to reduce the number of power supplies required for high-power applications, improving space utilization and minimizing the risk of failure.

Fig 4. XF family of configurable power supply

Fig 4. XF family of configurable power supply

The AE XF family offers 400 to 1000 W modular power solutions designed for reliability, compactness, and durability in harsh environments. Offering up to 12 isolated outputs, the XF products can provide output voltages up to 348 VDC. The plug-and-play architecture offers maximum flexibility, allowing configuration of custom power solutions in less than five minutes. The XF family of configurable power supplies meets MIL-STD vibration, shock and operating temperature ranges.

Testing and calibration

Finally, it is worth noting that alongside selecting best-in-class power solutions, electrical testing and calibration are also important to system reliability and performance in the defense and aerospace markets. That’s why AE also offers a range of products for the rapid testing of the integrity of electrical bonds that are critical to both system performance and electromagnetic compatibility.

For the precise resistance measurement of critical connections, bond meters and milli-ohmmeters, such as AE’s 720A Intrinsically Safe model, support proper installation and verification of power distribution networks. For RF power measurement, the PMX18-CS-02-01 enables highly accurate power measurement and calibration to ensure effective communication links and regulatory compliance.

Conclusion

The good news is that recent innovations are making a big difference. These innovations increase efficiency, reduce cooling requirements, and drive down form factors and weight while reducing cost. They are supported by comprehensive testing and calibration tools. Together, these advances are helping defense and aerospace manufacturers meet both SWaP and reliability criteria. This is especially important for critical AC-DC power supplies and DC-DC converters. These components power sensitive electronics and ensure safe, dependable operation in rugged conditions. Finally, AE’s defense products undergo rigorous testing and are compliant with military standards and regulations.

For further information on Advanced Energy’s offering for the aerospace and defense sector, please visit our dedicated applications page.

- https://www.verifiedmarketreports.com/product/military-grade-cots-power-supply-market/

- AE products and services are commercial in nature and are not International Traffic in Arms Regulations (ITAR) compliant.

Todd Hendrix

Advanced Energy

Todd Hendrix currently serves as director, strategic marketing within System Power at Advanced Energy

更多文章 Todd Hendrix